GHG Emissions from Forest Operations in Mediterranean Chestnut Coppices

doi: https://doi.org/10.5552/crojfe.2026.4020

volume: 47, issue: 1

pp: 13

- Author(s):

-

- Picchio Rodolfo

- Latterini Francesco

- Venanzi Rachele

- Article category:

- Original scientific paper

- Keywords:

- skidder, forwarder, chainsaw, excavator–based harvesting

Abstract

HTML

This study investigated the greenhouse gas (GHG) emissions associated with various mechanisation levels and extraction methods in Mediterranean chestnut (Castanea sativa L.) coppice forests. Located in central Italy, these forests play a significant role in economic as well as ecological terms. This study addressed a critical gap in emissions data for broadleaf forest operations by examining the productivity and environmental impact of four logging systems. These systems integrate semi-mechanised and mechanised felling methods with skidding and forwarding extraction techniques. The results revealed that mechanised felling significantly boosts productivity by 44–66% compared to semi-mechanised felling but generates over three times the GHG emissions per cubic meter of wood. Notably, extraction operations account for the largest share of total emissions, with skidding emitting nearly three times more than forwarding, primarily due to its lower work productivity. Specifically, forwarding in a Cut-to-Length (CTL) system achieved productivity of over double that of skidding and reduced emissions per cubic meter of extracted wood by up to 63%. Key findings suggested that improving work productivity through optimised extraction methods, operator training, and efficient road network layouts can substantially lower emissions. Among the systems tested, CTL forwarding paired with mechanised felling showed the highest productivity and lowest emissions, presenting a promising model for sustainable chestnut coppice management in Mediterranean regions.

GHG Emissions from Forest Operations in Mediterranean Chestnut Coppices

Rodolfo Picchio, Francesco Latterini, Rachele Venanzi

https://doi.org/10.5552/crojfe.2026.4020

Abstract

This study investigated the greenhouse gas (GHG) emissions associated with various mechanisation levels and extraction methods in Mediterranean chestnut (Castanea sativa L.) coppice forests. Located in central Italy, these forests play a significant role in economic as well as ecological terms. This study addressed a critical gap in emissions data for broadleaf forest operations by examining the productivity and environmental impact of four logging systems. These systems integrate semi-mechanised and mechanised felling methods with skidding and forwarding extraction techniques. The results revealed that mechanised felling significantly boosts productivity by 44–66% compared to semi-mechanised felling but generates over three times the GHG emissions per cubic meter of wood. Notably, extraction operations account for the largest share of total emissions, with skidding emitting nearly three times more than forwarding, primarily due to its lower work productivity. Specifically, forwarding in a Cut-to-Length (CTL) system achieved productivity of over double that of skidding and reduced emissions per cubic meter of extracted wood by up to 63%. Key findings suggested that improving work productivity through optimised extraction methods, operator training, and efficient road network layouts can substantially lower emissions. Among the systems tested, CTL forwarding paired with mechanised felling showed the highest productivity and lowest emissions, presenting a promising model for sustainable chestnut coppice management in Mediterranean regions.

Keywords: skidder, forwarder, chainsaw, excavator–based harvesting

1. Introduction

Forests are essential to the global carbon cycle, serving as critical carbon sinks (Daigneault et al. 2022, Puchałka et al. 2024). In the face of climate change, forest management strategies increasingly focus on maximising carbon sequestration while minimising greenhouse gas (GHG) emissions from forest operations (Verkerk et al. 2020). Accurately quantifying these emissions is now a priority, as reliable data on the GHG impacts of forest operations are essential for guiding sustainable forest management, shaping policy, and enhancing reporting on international climate goals (Schweier et al. 2019). However, the emissions associated with forest management practices in broadleaf stands remain poorly understood, particularly compared to the more extensively studied coniferous forests (Kärhä et al. 2024).

Time-motion studies in forest operations are essential for accurately assessing work efficiency, fuel consumption, and equipment usage, which are critical inputs for estimating greenhouse gas (GHG) emissions and assessing the overall sustainability of forest operations (Borz et al. 2025, Stoilov et al. 2024). By linking operational productivity with GHG analysis, these studies help identify opportunities to reduce emissions, improve sustainability, and guide the development of low-impact forestry practices (Borz et al. 2021). Among broadleaf forests, chestnut (Castanea sativa Mill.) stands are particularly significant in central and southern Italy, serving as a vital resource for both ecological sustainability and economic development (Marziliano et al. 2022). Italy hosts one of the largest areas of chestnut forests in Europe, covering approximately 800,000 hectares, mostly located in the Apennine Mountains as well as other parts of central and southern regions (Gasparini and Tabacchi 2011). These forests are not only valuable for their high carbon sequestration potential but also for their multifunctional role in rural economies (Marcolin et al. 2020). Chestnut wood is highly valued for its durability and quality, and chestnut forests are an important source of timber, non-timber products (such as chestnuts and mushrooms), and recreational opportunities (Patrício et al. 2020). Additionally, chestnut stands contribute to biodiversity conservation, soil protection, and hydrological stability, offering essential ecosystem services that benefit both local communities and broader environmental health (De Feudis et al. 2021).

Despite their ecological and economic benefits, chestnut stands, like other broadleaf forests, contribute to GHG emissions through forest operations such as felling, processing, bunching, extraction, and chipping (Đuka et al. 2024). These activities involve fossil fuel combustion, resulting in direct CO₂ as well as other pollutant emissions (Latterini et al. 2022b).

Research suggests that forest operations can account for a significant portion of a forest's overall GHG footprint, particularly when they involve advanced mechanisation levels (Klein et al. 2015, de la Fuente et al. 2017). In Italy, where chestnut forests are often managed for both conservation and productive purposes, understanding the GHG emissions from different phases of forest operations is crucial for creating sustainable management guidelines that balance carbon storage with timber and non-timber outputs (Del Giudice et al. 2024).

Previous research on GHG emissions from forest operations has mostly focused on coniferous forests in boreal and temperate regions, where standard practices and machinery tend to be well–documented and widely applicable (Kärhä et al. 2024). However, broadleaf stands, and chestnut forests in particular, exhibit unique structural and compositional characteristics, which can influence the type, intensity, and frequency of management interventions. Compared to coniferous forests, broadleaf forests generally have higher biomass densities, which can lead to greater emissions during felling and extraction activities (de la Fuente et al. 2022). Moreover, chestnut forests, and more generally broadleaf forests in the Italian Apennine, are often located in mountainous areas with challenging topographies that may have an impact on machinery productivity and related environmental concerns (Latterini et al. 2023b, Latterini et al. 2024a). These unique conditions imply that findings from studies on GHG emissions in coniferous forests may not be directly transferable to chestnut-dominated ecosystems, further making evident the need for region- and species-specific studies. Furthermore, it is worth highlighting that GHG analysis studies dealing with Castanea species are rare and concern either high-intensity management systems (Lu et al. 2019) or focus on the overall rotation cycle (Prada et al. 2016). As a result, there are no studies in the current literature that specifically focus on forest operation-related GHG emissions. These are in fact the major part of the total GHG emissions along the rotation cycle in chestnut stands.

It is important to note that advanced mechanisation, including mechanised felling and forwarder-based extraction, was introduced in the Mediterranean context relatively recently, about 10–15 years ago (Laina et al. 2013, Schweier et al. 2015). This makes it an opportune time to assess whether this machinery has been successfully integrated into forest operations, particularly whether operators have acquired the necessary experience and technical expertise to use it as effectively as traditional systems.

Taking the above into account, this research was developed to test the work productivity and GHG emissions related to different forest operations in Central Italy chestnut coppices. Specifically, we analysed the influence of felling type (motor–manual vs mechanised) and extraction mean (skidder vs forwarder) on the overall GHG emissions related to the forest operations up to the landing site; thus considering felling, processing, bunching, extraction and chipping.

The findings of this study hold several important implications. First, they enhance the understanding of GHG emissions associated with forest operations in broadleaf stands, addressing a critical gap in the existing research. Second, by focusing on chestnut forests, the study provides emissions data specific to a forest type that is both economically and culturally significant in Mediterranean regions. Finally, it offers actionable recommendations for forest managers and policymakers aiming to reduce emissions and improve the carbon balance of forest operations in Italy and comparable Mediterranean ecosystems.

2. Materials and Methods

2.1 Study Site and Harvesting Methods

The study area (WGS84UTM33 Coordinate 264958 East, 4670207 North) corresponds to a logging site harvested during the harvesting season 2022–2023 (October 2022–May 2023) located in the municipality of Bracciano (Latium, Italy). The logging site was an almost pure chestnut coppice, in which chestnut represented more than 95% of the standing volume. Accompanying species were Quercus cerris L., Fraxinus ornus L. and Acer campestre L. The total surface of the logging site was 28 ha. Slope was constant along the overall surface and equivalent to 15%. Prevalent aspect was South-West. Terrain roughness (presence of obstacles to the movement of mechanic means) was negligible. Stand age at the moment of harvesting was 18 years, with a standing volume of 185 m3 ha-1. The silvicultural treatment was a coppicing with 60 standards per hectare, as is common in chestnut coppice in Italy, resulting in a harvested volume of 165 m3 ha-1.The 28 ha of the logging sites were subdivided into four plots of 7 ha each. Each plot consisted of a combination of felling and extraction systems (i.e. experimental treatments), namely: motor-manual felling by chainsaw and extraction by cable skidder; motor-manual felling by chainsaw and extraction by forwarder; mechanised felling by excavator-based rotating shear and extraction by cable skidder; mechanised felling by excavator-based rotating shear and extraction by forwarder. The technical characteristics of the analysed machinery are as follows:

Chainsaw Stihl MS440, 4 kW engine, 50 cm cutting bar

Excavator SANY SY155U, 16.5 tons, 78.5 kW engine equipped with a rotating shear COMAF GD350 for a diameter up to 35 cm

Forwarder John Deere 1210G, 156 kW engine, operating weight 31.0 tons

Cable skidder John Deere 648 H 138 kW engine, operating weight 13.7 tons

In the plots in which the skidder was used for timber extraction, the whole-tree system (WTH) was applied. In the plots where extraction operations were carried out by forwarding, the Cut-to-Length (CTL) system was applied. All the operations for each experimental treatment were carried out by operators with a similar level of experience of at least 15 years.

2.2 Time-motion Studies

A time-motion study was conducted to quantify the productivity and efficiency of the forest operations. Data collection took place during winter–spring 2023, covering ten working days for each experimental treatment. Observations were made using direct in-field methods with handheld devices, and time data were recorded to the nearest second. Additionally, video recordings were made for post-analysis, allowing for precise timing and coding of activities.

The study utilised continuous timing techniques to record operational cycles, as outlined in the methods of Spinelli and Visser (2009) and Magagnotti et al. (2021). Each operational cycle was divided into key phases, namely moving, cleaning, felling and processing for felling/processing operations; travel unload, loading, travel load and unloading for forwarding; and travel unload, bunching, travel load and piling for skidding. A description of the various phases for the working cycle is reported in Table A1 in the appendix. Winching, skidding and forwarding distances were recorded for each working cycle using both a measuring tape and a GNSS handheld receiver.

These tasks were classified based on a standardised classification system in forest operations studies: productive time (time spent on core operational tasks); unavoidable delays (refuelling, repairs, and operator rest periods) and avoidable delays (personal breaks, idle machine time).

Time-motion analysis for tree felling was conducted by selecting and marking 100 stumps for each experimental treatment using spray paint. For each stump, the diameter at breast height (DBH) and height of all shoots were measured, and the volume was estimated using local dendrometric tables. Productivity evaluation focused on analysing work cycles, defined as the time required to fell and process all the shoots of a single stump. For bunching and extraction operations, the work cycle was defined as the time taken to complete the loading of the extraction unit. Therefore, 400 working cycles (100 x 4 experimental treatments) were analysed for both felling/processing and extraction.

After calculating the working times and shoot volumes for each operational cycle, net productivity was determined in cubic meters per productive machine hour (m³ PMH⁻¹), which excludes delays, while gross productivity was measured in cubic meters per scheduled machine hour (m³ SMH⁻¹), accounting for delays. It is important to note that the analysis was concluded at the landing site, excluding the time required for loading and transporting the logs. Furthermore, it is worth noticing that at the landing site the processing phase was carried out for the material derived from the skidding plots, and that the wooden material which could not be sold as structural timber or poles was chipped by a Pezzolato PTH 1200/1000 stationary chipper powered by a Claas Xerion 4500 tractor. Processing phase for skidding plots and chipping of the residual biomass were not analysed statistically, considering that the comparison among the felling and extraction methods at the base of the experimental design was not applicable for these operations. However, the emissions related to chipping operation and to processing at the landsite of skidded biomass were included in the overall calculation of pollutant emissions.

2.3 GHG Emission Analysis

The scope of the analysis included the operations of felling, processing, bunching, and timber extraction, with the reference flow defined as 1 m³ of wood extracted. Emissions of pollutants were linked to diesel usage, which was quantified through the fuel refill method. These emissions accounted for both direct emissions from fuel combustion and indirect emissions related to fuel production and distribution. Combustion-related emissions were estimated based on the energy content of the fuel, engine output, specific emission factors, and combustion efficiency. Carbon dioxide (CO₂) emissions were computed following the methodology proposed by Athanassiadis (2000), while carbon monoxide (CO), nitrogen oxides (NOₓ), and particulate matter (PM) emissions were estimated using formulas and emission coefficients provided by Klvac et al. (2012). Emissions from fuel combustion (EFC) were calculated according to Eq. (1):

Where:

Fc fuel consumption, L m-³ of wood

Ef emission factor linked to engine power, g MJ-1

Cv fuel calorific value, MJ L-1

Te thermal efficiency percentage.

Emissions from fuel production and supply chain (EFP) were assessed using the approach reported by Klvac et al. (2012), with an emission factor of HC as recommended by Athanassiadis (2000), following Eq. (2):

Additionally, emissions associated with oil consumption were evaluated as the sum of emissions from oil production (EOP, in g m-³ of wood) and emissions from the reprocessing of waste oil for combustion (EOR, in g m-³ of wood). EOP and EOR were calculated using Eq. (3) and (4):

Where:

Oc oil consumption, L m-³

Ef emission factor, g L-1.

Finally, emissions from GHGs (CO₂, CH₄, and N₂O) were converted to equivalent carbon dioxide (kg CO₂eq) by applying characterisation factors, translating the mass of these pollutants into the mass of CO₂ that would yield an equivalent climate warming potential (Weyrens et al. 2022).

2.4 Statistical Analysis

A preliminary statistical analysis by one-way ANOVA was carried out to check for the presence of statistically significant differences (p<0.05) in the dendrometric features of the analysed stumps in the four plots. Furthermore, the forwarding and skidding distances were analysed in the same way. These preliminary analyses allowed us to avoid the influence of dendrometric and logistic variables on the productivity and GHG emission results.

The main statistical analysis was performed to check the effects of the felling system and extraction system on the working times. Considering that our experimental design is based on a case-study approach without involving any nested data structure, we used linear models in a one-way ANOVA.The factor considered was the experimental treatment that had four levels: SM–S: semi mechanised felling and extraction by skidder; SM–F: semi mechanised felling and extraction by forwarder; MEC–S: mechanised felling and extraction by skidder; MEC–F: mechanised felling and extraction by forwarder. In the case the assumption of data normality and homoscedasticity were not confirmed by Shapiro–Wilk and Levene test, respectively, a logarithmic transformation was applied to normalise the data by using the formula log (x+1). This transformation helps to reduce the skewness in the data, making it closer to a normal distribution.Adding 1 before applying the logarithm ensures that zero and negative values are handled appropriately, as the logarithm of zero or negative values is undefined. For the variables that showed to be statistically significantly (p<0.05) influenced by the factors, we used the Tukey HSD test as post–hoc.R software (R Development Core Team 2023) was used to conduct the statistical analysis, specifically the package lme4 (Bates et al. 2015), car (Fox et al. 2012) and emmeans (Lenth et al. 2019).Linear models were further used to investigate the relationships between time consumption during felling and processing and several explanatory variables: the felling system (semi-mechanised vs. mechanised), the number of shoots per stump, shoot volume, and stump volume.Additionally, linear models were applied to examine how time consumption during extraction operations was influenced by the extraction system (skidder vs. forwarder) and extraction distance.

2.5 Study Data

The preliminary analysis assessed the influence of dendrometric and logistical variables on the experimental treatments, confirming that the experimental design was unbiased in these aspects. Most variables showed no statistically significant differences among treatments (Table 1). Therefore, the results of the time-motion studies reflect the intrinsic differences among the experimental treatments rather than the characteristics of the study plots. The only variable that showed a significant difference was the load volume, considering that obviously a forwarder has a higher load volume than a cable skidder. However, the load volume was not significantly different between the two plots extracted by the skidder (semi-mechanised and mechanised) and between the two plots extracted by forwarder (semi-mechanised and mechanised). It is important to note that using a 13.7-ton skidder to extract approximately 2 m³ per cycle may appear oversized. However, in chestnut coppices, the extraction involves not only small–diameter shoots but also standards, which are significantly larger and hold greater economic value. Each standard can reach volumes of around 1 m³. Additionally, the extraction process often involves multiple small stems (shoots) being removed simultaneously. In such cases, the winch capacity is typically reached based on the number of stems rather than the total volume, making machine performance more dependent on handling complexity than raw load size.

Table 1 Average dendrometric and logistic features in the investigated experimental treatments. Acronyms: SM–S: semi mechanised felling and extraction by skidder; SM–F: semi mechanised felling and extraction by forwarder; MEC–S: mechanised felling and extraction by skidder; MEC–F: mechanised felling and extraction by forwarder. Same lowercase letters in the columns of the experimental treatments indicate homogeneous groups at p<0.05 according to Tukey post-hoc test

|

Variable |

SM–S |

SM–F |

MEC–S |

MEC–F |

p value of one–way ANOVA |

|

N. shoot per stump |

4.5 |

4.5 |

4.3 |

4.5 |

>0.05 |

|

Stump volume, m3 |

0.974 |

0.978 |

0.944 |

0.991 |

>0.05 |

|

Bunching distance, m |

60.05 |

n.a. |

61.10 |

n.a. |

>0.05 |

|

Extraction distance, m |

1010 |

1185 |

1008 |

1191 |

>0.05 |

|

Volume of a load, m3 |

2.009 a |

14.441 b |

2.228 a |

14.994 b |

<0.001 |

3. Results

3.1 Working Time and Work Productivity Analysis

For felling operations, there is a clear trend of reduced time consumption when using mechanised felling (Table 2). This reduction applies not only to the actual felling phase but also to the preliminary tasks, such as moving and cleaning. At the same mechanisation level, the total working time - both net and gross - was lower with the WTH system (skidding plots) compared to the CTL system (forwarding plots). This difference is attributed to the absence of an on-site processing phase in the WTH system, which is instead performed later at the landing site, as well as the lower impact of unavoidable delays (Table 2).

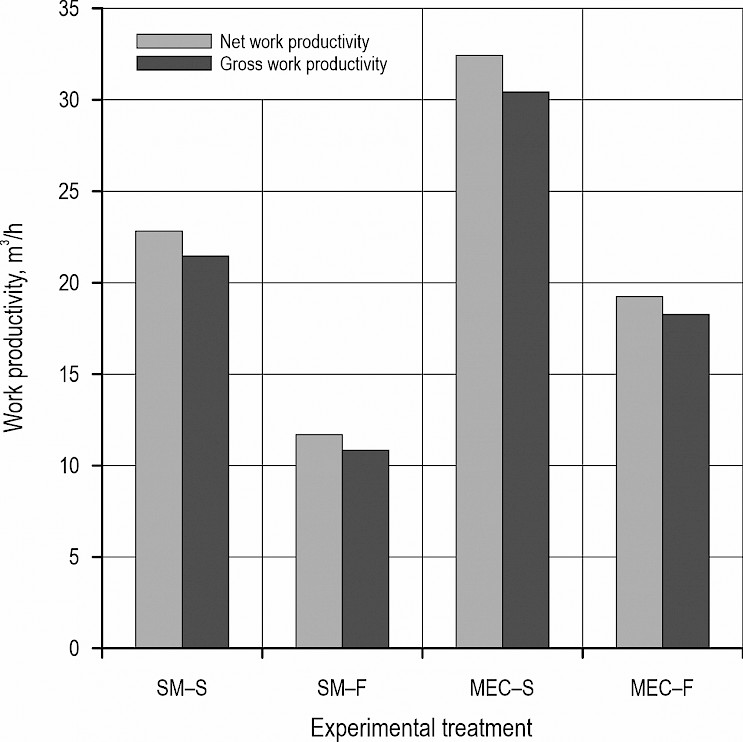

The analysis of the productivity of the overall felling operations showed that a higher mechanisation level led to higher work productivity, and that the highest productivity value was achieved when using the WTH in a mechanised way (Fig. 1). Specifically, gross work productivity for mechanised felling resulted 41% and 65% higher in comparison to semi-mechanised felling in the skidding and forwarding plots, respectively. Considering net work productivity, the increase when using mechanised felling was 44% and 66%, respectively, for skidding and forwarding plots.

Table 2 Average time-consumption (min cycle-1) for felling operation. Same lowercase letters in the columns of the experimental treatments indicate homogeneous groups at p<0.05 according to Tukey post–hoc test. Acronyms: SM–S: semi mechanised felling and extraction by skidder; SM–F: semi mechanised felling and extraction by forwarder; MEC–S: mechanised felling and extraction by skidder; MEC–F: mechanised felling and extraction by forwarder

|

Variable |

SM–S |

SM–F |

MEC–S |

MEC–F |

p value of one–way ANOVA |

|

Moving time, min |

0.19 a,b |

0.21 c |

0.17 a |

0.19 b |

<0.001 |

|

Cleaning time, min |

0.76 b |

0.89 c |

0.58 a |

0.57 a |

<0.001 |

|

Felling time, min |

1.46 b |

1.44 b |

0.86 a |

0.96 a |

<0.001 |

|

Processing time, min |

n.a.* |

1.56 b |

n.a.* |

0.85 a |

<0.01 |

|

Avoidable delay, % |

5.1 |

6.5 |

6.4 |

7.0 |

>0.05 |

|

Unavoidable delay, % |

6.3 a |

16.9 b |

7.3 a |

15.3 b |

<0.01 |

|

Total time excluding delay, min |

2.41 a |

4.10 b |

1.61 a |

2.58 a |

<0.001 |

|

Total time including delay, min |

2.72 a,b |

5.35 c |

1.86 a |

3.32 b |

<0.001 |

|

* In the plots extracted by skidder the whole–tree system was applied, thus processing operation was carried out at the landing site |

|||||

Fig. 1 Work productivity for felling operation in four investigated experimental treatments. Acronyms: SM–S: semi mechanised felling and extraction by skidder; SM–F: semi mechanised felling and extraction by forwarder; MEC–S: mechanised felling and extraction by skidder; MEC–F: mechanised felling and extraction by forwarder

The analysis of factors influencing time consumption showed that only the felling and processing system (mechanised vs. semi-mechanised) had a statistically significant effect, with mechanised operation showing lower time-consumption than the semi mechanised one. In contrast, stump characteristics did not significantly affect time consumption (Table 3).

Table 3 Results of linear models analysing the effects of felling system, number of shoots per stump, shoot volume and stump volume on time consumption for felling and processing operation. SM = Semi-mechanised system (compared to mechanised reference – MEC which is the intercept in the model). Significance codes: »***« p<0.001

|

Predictor |

Estimate |

Std. error |

t–value |

p–value |

Significance |

|

Intercept |

1.164 |

0.695 |

1.675 |

0.095 |

– |

|

Felling system (SM) |

0.308 |

0.048 |

6.440 |

<0.001 |

*** |

|

Number of shoots |

–0.089 |

0.145 |

–0.618 |

0.537 |

– |

|

Shoot volume, m³ |

–0.209 |

3.119 |

–0.067 |

0.947 |

– |

|

Stump volume, m³ |

0.426 |

0.646 |

0.659 |

0.510 |

– |

|

Adjusted R2 |

0.0852 |

||||

|

F statistic |

11.22 |

||||

|

p value |

<0.001 |

||||

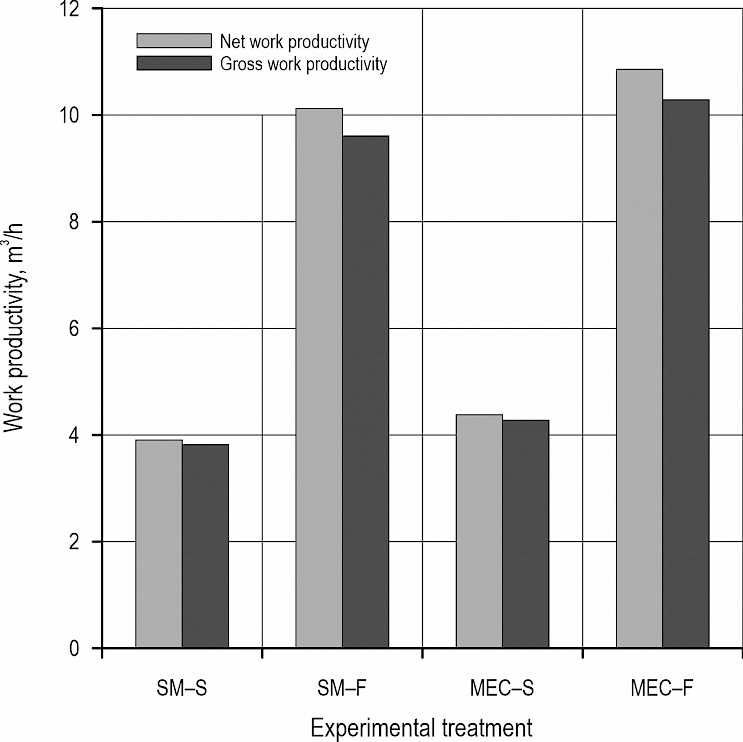

Focusing on extraction operations, the results in Table 4 show a significant impact of the machinery used on working times, whereas the level of mechanisation employed for felling had a negligible effect (Table 4). Skidding resulted in lower working times for all the investigated phases. This was expected for bunching/loading, but we also found a significant difference for travel load and travel unload phases. However, the higher volume per load of the forwarder in comparison to the skidder made the work productivity of forwarding substantially higher than skidding (Fig. 2). Specifically, forwarder productivity in both the mechanised-felled and semi-mechanised felled plots was more than double that of the skidder (Fig. 2).

Table 4 Average time consumption (min cycle-1) for extraction operation. Same lowercase letters in the columns of the experimental treatments indicate homogeneous groups at p<0.05 according to Tukey post–hoc test. Acronyms: SM–S: semi mechanised felling and extraction by skidder; SM–F: semi mechanised felling and extraction by forwarder; MEC–S: mechanised felling and extraction by skidder; MEC–F: mechanised felling and extraction by forwarder

|

Variable |

SM–S |

SM–F |

MEC–S |

MEC–F |

p value of one–way ANOVA |

|

Travel unload, min |

6.27 a |

14.40 b |

6.21 a |

14.49 b |

<0.001 |

|

Bunching/Loading*, min |

3.06 a |

34.93 c |

2.10 a |

31.56 b |

<0.001 |

|

Travel load, min |

8.71 a |

18.53 b |

8.33 a |

18.42 b |

<0.001 |

|

Piling/Unloading *time, min |

6.56 a |

9.25 b |

6.53 a |

9.48 b |

<0.001 |

|

Avoidable delay, % |

2.1 a |

5.1 b |

2.2 a |

5.3 b |

<0.001 |

|

Unavoidable delay, % |

1.4 a |

8.4 b |

1.6 a |

9.3 b |

<0.001 |

|

Total time excluding delay, min |

24.1 a |

77.1 b |

23.2 a |

73.9 b |

<0.001 |

|

* Bunching and piling refer to skidding; loading and unloading to forwarding |

|||||

Fig. 2 Work productivity for extraction operation in four investigated experimental treatments. Acronyms: SM–S: semi mechanised felling and extraction by skidder; SM–F: semi mechanised felling and extraction by forwarder; MEC–S: mechanised felling and extraction by skidder; MEC–F: mechanised felling and extraction by forwarder

The linear model analysis revealed that all investigated variables, extraction system, extraction distance, and load volume, had statistically significant effects on time consumption (Table 5). Specifically, longer extraction distances and larger load volumes were associated with increased time consumption.

Table 5 Results of linear models analysing the effects of extraction system, extraction distance, and load volume on time consumption for extraction operation. S = Skidder (compared to forwarder reference – F which is the intercept in the model). Significance codes: »***« p<0.001, »**« p<0.01

|

Predictor |

Estimate |

Std. error |

t–value |

p–value |

Significance |

|

Intercept |

3.501 |

0.145 |

24.090 |

<0.001 |

*** |

|

Extraction system, S |

–0.344 |

0.124 |

–2.773 |

0.006 |

** |

|

Extraction distance, m |

0.00025 |

0.00003 |

8.771 |

<0.001 |

*** |

|

Load volume, m³ |

0.028 |

0.010 |

2.862 |

0.004 |

** |

|

Adjusted R2 |

0.761 |

||||

|

F statistic |

425 |

||||

|

p value |

<0.001 |

||||

3.2 Calculated GHG Emissions

GHG emissions related to felling operation were substantially higher when using mechanised felling (Table 6). This trend was evident for both the skidding and forwarding plots. Emissions when using the mechanised system resulted more than three times higher than when using semi-mechanised felling. Furthermore, emissions in the forwarding plots resulted higher than in skidding plots, but this is related to the fact that processing operation was performed at the stump in the forwarding plots, while at the landing site for skidding plots.

Table 6 GHG emissions related to felling operation. Acronyms: SM–S: semi mechanised felling and extraction by skidder; SM–F: semi mechanised felling and extraction by forwarder; MEC–S: mechanised felling and extraction by skidder; MEC–F: mechanised felling and extraction by forwarder; CO2: carbon dioxide; CO: carbon monoxide; HC: hydrocarbons; NOx: nitric oxides; PM: particulate matter

|

CO2 |

CO |

HC |

NOx |

PM |

|

|

g m-3 |

|||||

|

SM–S |

598.5 |

5.2 |

0.6 |

9.4 |

1.2 |

|

SM–F |

1182.4 |

10.3 |

1.1 |

18.5 |

2.4 |

|

MEC–S |

2144.8 |

20.0 |

2.7 |

35.9 |

3.4 |

|

MEC–F |

3632.4 |

33.9 |

4.6 |

60.8 |

5.7 |

Concerning the GHG emissions related to extraction operation, on equal mechanisation level, forwarding extraction resulted to emit much less GHG than skidding extraction (Table 7). This was due to the higher work productivity achieved by forwarding, which resulted in lower GHG emissions per cubic meter of extracted wood. GHG emissions in forwarding resulted almost three times lower than in skidding. It is important to notice that extraction operation was the most impactful in terms of GHG emissions in comparison to felling and also chipping operations (Table 8).

Table 7 GHG emissions related to extraction operation. Acronyms: SM–S: semi mechanised felling and extraction by skidder; SM–F: semi mechanised felling and extraction by forwarder; MEC–S: mechanised felling and extraction by skidder; MEC–F: mechanised felling and extraction by forwarder; CO2: carbon dioxide; CO: carbon monoxide; HC: hydrocarbons; NOx: nitric oxides; PM: particulate matter

|

CO2 |

CO |

HC |

NOx |

PM |

|

|

g m-3 |

|||||

|

SM–S |

15538.1 |

161.6 |

16.5 |

264.4 |

23.7 |

|

SM–F |

6111.8 |

63.5 |

6.5 |

104.0 |

9.3 |

|

MEC–S |

13844.4 |

143.9 |

14.7 |

235.6 |

21.1 |

|

MEC–F |

5717.2 |

59.4 |

6.1 |

97.3 |

8.7 |

Table 8 GHG emissions related to chipping operation. This operation did not differ among the experimental treatments because the residual biomass was chipped all together at the landing site after the end of the other operations; CO2: carbon dioxide; CO: carbon monoxide; HC: hydrocarbons; NOx: nitric oxides; PM: particulate matter

|

CO2 |

CO |

HC |

NOx |

PM |

|

g m-3 |

||||

|

2066.6 |

20.6 |

2.4 |

30.9 |

3.2 |

The total emissions per each experimental treatment are reported in Table 9. Skidding emissions resulted higher than forwarding emissions, mostly as a consequence of the lower work productivity. The influence of the felling system is much less evident when considering the overall forest operations, further confirming that extraction operation is the most impactful part of logging in terms of GHG emissions. Skidding also resulted in higher emissions related to oil consumption then forwarding, even if the contribution of oil consumption to the overall GHG emissions of the forest operations is practically negligible.

Table 9 Total GHG emissions for various investigated experimental treatments. CO2: carbon dioxide; CO: carbon monoxide; HC: hydrocarbons; NOx: nitric oxides; PM: particulate matter. Acronyms: SM–S: semi mechanised felling and extraction by skidder; SM–F: semi mechanised felling and extraction by forwarder; MEC–S: mechanised felling and extraction by skidder; MEC–F: mechanised felling and extraction by forwarder; EFC: emissions related to fuel combustion; EFP: emissions related to fuel production; EOP: emissions related to oil production; EOR: emissions related to reprocessing of waste oil for combustion

|

CO2 |

CO |

HC |

NOx |

PM |

|

|

g m-3 |

|||||

|

SM–S |

|||||

|

EFC |

17070.3 |

184.0 |

6.5 |

296.7 |

27.3 |

|

EFP |

1110.0 |

1.2 |

12.7 |

6.5 |

0.0 |

|

EFC+EFP |

18180.3 |

185.2 |

19.2 |

303.1 |

27.3 |

|

EOP |

19.0 |

1.7 |

0.3 |

1.6 |

0.5 |

|

EOR |

4.1 |

0.5 |

0.0 |

0.0 |

0.3 |

|

EOP+EOR |

23.0 |

2.2 |

0.3 |

1.6 |

0.8 |

|

TOT |

18203.3 |

187.4 |

19.4 |

304.7 |

28.1 |

|

SM–F |

|||||

|

EFC |

8778.3 |

92.8 |

3.3 |

149.4 |

14.5 |

|

EFP |

570.8 |

0.6 |

6.5 |

3.3 |

0.0 |

|

EFC+EFP |

9349.1 |

93.4 |

9.8 |

152.6 |

14.5 |

|

EOP |

9.8 |

0.8 |

0.1 |

0.8 |

0.3 |

|

EOR |

2.1 |

0.3 |

0.0 |

0.0 |

0.1 |

|

EOP+EOR |

11.8 |

1.1 |

0.1 |

0.8 |

0.4 |

|

TOT |

9360.9 |

94.5 |

10.0 |

153.4 |

14.9 |

|

MEC–S |

|||||

|

EFC |

16932.0 |

181.3 |

6.6 |

294.4 |

26.9 |

|

EFP |

1101.0 |

1.1 |

12.9 |

6.3 |

0.0 |

|

EFC+EFP |

18032.9 |

182.4 |

19.5 |

300.8 |

26.9 |

|

EOP |

18.8 |

1.6 |

0.2 |

1.6 |

0.5 |

|

EOR |

4.0 |

0.5 |

0.0 |

0.0 |

0.2 |

|

EOP+EOR |

22.8 |

2.2 |

0.2 |

1.6 |

0.8 |

|

TOT |

18055.7 |

184.6 |

19.8 |

302.4 |

27.7 |

|

MEC–F |

|||||

|

EFC |

10705.7 |

111.9 |

4.3 |

184.0 |

17.1 |

|

EFP |

696.1 |

0.7 |

8.5 |

3.9 |

0.0 |

|

EFC+EFP |

11401.9 |

112.6 |

12.9 |

188.0 |

17.1 |

|

EOP |

11.9 |

1.0 |

0.1 |

1.0 |

0.3 |

|

EOR |

2.5 |

0.3 |

0.0 |

0.0 |

0.1 |

|

EOP+EOR |

14.4 |

1.4 |

0.1 |

1.0 |

0.5 |

|

TOT |

11416.3 |

113.9 |

13.1 |

189.0 |

17.6 |

4. Discussion

The use of a fully mechanised system for felling operation resulted in higher work productivity (Fig. 1) and higher GHG emissions (Table 5). This was expected and confirmed the literature findings in the topic (Spinelli et al. 2014, Liepiņš et al. 2015, Latterini et al. 2023a). However, looking at the details of the various phases of felling operation (Table 2), it can be noticed that the mechanised system was less time-consuming than the semi-mechanised one not only for the felling and processing phase, but also for moving and cleaning phases. Furthermore, the results reported in Table 2 also showed that there was no statistically significant difference in the avoidable delays between the mechanised system and the semi-mechanised one. These findings highlighted that, in the study context, the operators used the excavator-based felling system with the same level of skill with which they use the typical chainsaw. It can therefore be concluded that the 10–15 years since the introduction of advanced mechanisation in the study context appear to have been sufficient for operators to reach a high level of confidence and skill. This is evidenced by their ability to use the excavator-based felling system without incurring increased delays compared to chainsaw operations (Burk et al. 2023). The results of the modelling analysis for felling operations (Table 3) confirmed that mechanised felling is less time-consuming than semi-mechanised felling. However, no statistically significant effects were found for the other investigated variables related to stump characteristics. While larger stem dimensions are typically associated with lower time consumption (Latterini et al. 2023a), this relationship was not observed in the present study. This is likely due to the limited variability in stump dimensions, which may have prevented a significant effect from being detected.

Focusing on extraction operation, the use of a forwarder led to higher work productivity than a cable skidder (Fig. 2), despite the higher time consumption related to forwarding (Table 4). It is obvious that loading and unloading of a forwarder is more time-consuming than winching and then unhooking the load of a cable skidder. However, as reported in Table 4, travel times also resulted higher for forwarding than for skidding, despite the similar extraction distances (Table 1). This is related to the lower operating speed of the forwarder. Although the observed delays were in line with the literature for both skidding and forwarding (Spinelli and Visser 2008), avoidable delays resulted significantly higher for forwarding than for skidding (Table 4). In the study context, forwarding operations already demonstrate high productivity but have significant potential for further improvement (Stoilov et al. 2024). This can be achieved by enhancing the experience and skills of the operators (Spinelli et al. 2021, Leszczyński 2023). Results of the model analysis (Table 5) confirm that extraction distance and load volume are important influencing factors for time-consumption in extraction operation (Louis et al. 2022).

Due to its higher work productivity, forwarding proved to be less impactful than skidding (Table 7), despite the greater engine power (156 kW vs. 136 kW). This finding supports the idea that improving work productivity also reduces GHG emissions (Kärhä et al. 2023, Kärhä et al. 2024). Based on our results, the Cut-to-Length (CTL) system using a forwarder is a suitable harvesting method for chestnut coppices in the Mediterranean region. This is attributed to its higher productivity, greater potential for reducing delays, and lower GHG emissions compared to the conventional Whole-Tree Harvesting (WTH) system using a cable skidder.

Our findings also confirmed that extraction operation is the most impactful in terms of GHG emissions (Tables 6, 7 and 8), because it is the operation with the most extensive use of mechanised machinery with big power engines. This leads to three important practical considerations retrievable from this study. First, the development of electric, hybrid or biofuel-powered extraction machinery should be prioritised (Mergl et al. 2021). It is however worth noticing that Lajunen et al. (2018) projected that forest machinery, which demands substantial power and operates beyond the range of fixed charging infrastructure in forests, is unlikely to be electrified in the coming years. Consequently, there are not many studies dealing with electric or hybrid forest machines. The only one in the current literature is the study by Poikela and Ovaskainen (2022), who focused on a hybrid harvester and found that its energy efficiency does not substantially exceed that of a traditional harvester powered by a combustion engine. However, there are opportunities to enhance the energy efficiency of forest machinery by minimising hydraulic system losses and incorporating hybrid technology (Englund et al. 2022). Given that increasing work productivity is the best way to decrease GHG emissions, a series of solutions can be applied towards this objective which include:

Improving the skills of the operators through specific types of training (Aalmo and Talbot 2014, Landekić et al. 2018, Burk et al. 2024)

Proper planning of the extraction routes by navigating gentle curves, making gradual turns, optimising payloads during extraction, and reducing the distance driven with a loaded machine within the stand (Amishev 2010, Ghaffariyan et al. 2018). This will also allow for reduced soil impacts related to ground-based extraction (Latterini et al. 2024a, Latterini et al. 2024b)

When possible, considering the environmental context, enhancing the layout of the forest road network by shortening the distance needed to transport wood from the harvesting site to the roadside landing area, thereby reducing fuel consumption and emissions (Picchio et al. 2018, Kühmaier et al. 2022, Latterini et al. 2022a)

Proper machine maintenance, such as regular greasing and cleaning of radiators and oil coolers (Amishev 2010, Kärhä et al. 2023)

Reducing idling time (Nordfjell et al. 2003).

Finally, considering that: i) forwarding resulted to have higher productivity and lower GHG emissions than skidding, and ii) despite higher emissions of the mechanised system in comparison to the semi-mechanised one, the influence of felling operation on the overall GHG emissions is minimal (Table 9); we recommend the Cut-to-Length system applied by mechanised felling and extraction by forwarder as the best suitable harvesting system among the investigated four alternatives.

Our findings reveal that the choice of machinery and method significantly impacts GHG emissions. Mechanised felling, although more productive, generates higher emissions during felling operations than the typical semi-mechanised system. However, extraction operations, particularly skidding, are the most impactful on overall emissions, largely due to the lower work productivity compared to forwarding. Notably, forwarding in a Cut-to-Length (CTL) system demonstrates both higher productivity and reduced emissions, making it a preferable system for chestnut coppice management in this context.

5. Conclusions

This study provides insights into the greenhouse gas (GHG) emissions associated with different mechanisation levels and extraction methods in Mediterranean chestnut coppices. The research fills a critical gap in the understanding of GHG emissions from broadleaf forest operations, specifically targeting chestnut stands in Central Italy, a region where such data is scarce but much needed for sustainable forest management.

Our findings reveal that the choice of machinery and method significantly impacts GHG emissions. Mechanised felling, although more productive, generates higher emissions during felling operations than the typical semi-mechanised system. However, extraction operations, particularly skidding, are the most impactful on overall emissions, largely due to the lower work productivity compared to forwarding. Notably, forwarding in a Cut-to-Length (CTL) system demonstrates both higher productivity and reduced emissions, making it a preferable system for chestnut coppice management in this context.

Funding

The research was funded by the statutory research of the Institute of Dendrology, Polish Academy of Sciences.

Acknowledgements

This study was carried out in cooperation with the Agritech National Research Center – WP 4.1 – Task 4.1.4 and received funding from the European Union Next-GenerationEU (PIANO NAZIONALE DI RIPRESA E RESILIENZA (PNRR) – MISSIONE 4 COMPONENTE 2, INVESTIMENTO 1.4 – D.D. 1032 17/06/2022, CN00000022). This manuscript reflects only the authors' views and opinions, neither the European Union nor the European Commission can be considered responsible for them.

6. References

Aalmo, G.O., Talbot, B., 2014: Operator performance improvement through training in a controlled cable yarding study. International Journal of Forest Engineering 25(1): 5–13. https://doi.org/10.1080/14942119.2014.904150

Amishev, D., 2010: A review of fuel consumption in New Zealand harvesting operations. Harvesting Technical Note 3(4): 1–5.

Athanassiadis, D., 2000: Energy consumption and exhaust emissions in mechanized timber harvesting operations in Sweden. Science of the Total Environment 255(1–3): 135–143. https://doi.org/10.1016/S0048-9697(00)00463-0

Bates, D., Mächler, M., Bolker, B., Walker, S., 2015: Fitting Linear Mixed-Effects Models Using lme4. Journal of Statistic Software 67(1): 1–48. https://doi.org/10.18637/jss.v067.i01

Borz, S.A., Oghnoum, M., Marcu, M.V., Lorincz, A., Proto, A.R., 2021: Performance of small-scale sawmilling operations: A case study on time consumption, productivity and main ergonomics for a manually driven bandsaw. Forests 12(6): 810. https://doi.org/10.3390/f12060810

Borz, S.A., Papandrea, S., Zoli, M., Bacenetti, J., Proto, A.R., 2025: Willow short rotation coppice. Energy and environmental assessment. Cleaner Environmental Systems 16: 100249. https://doi.org/10.1016/j.cesys.2024.100249

Burk, E., Han, H.S., Smidt, M., Fox, B. 2023: Effectiveness of simulator training compared to machine training for equipment operators in the logging industry. International journal of forest engineering 34(3): 373–384. https://doi.org/10.1080/14942119.2023.2194751

Burk, E., Han, H-S., Smidt, M., Fox, B., 2024: Incorporating Simulators into a Training Curriculum for Forestry Equipment Operators: A Literature Review. Croatian Journal of Forest Engineering 45(1): 199–216. https://doi.org/10.5552/crojfe.2024.2142

Daigneault, A., Baker, J.S., Guo, J., Lauri, P., Favero, A., Forsell, N., Johnston, C., Ohrel, S.B., Sohngen, B., 2022: How the future of the global forest sink depends on timber demand, forest management, and carbon policies. Global Environmental Change 76: 102582. https://doi.org/10.1016/j.gloenvcha.2022.102582

De Feudis, M., Falsone, G., Vittori Antisari, L., 2021: Mid-term (30 years) changes of soil properties under chestnut stands due to organic residues management: An integrated study. Catena (Amst) 198: 105021. https://doi.org/10.1016/j.catena.2020.105021

de la Fuente, T., Bergström, D., Fernandez-Lacruz, R., Hujala, T., Krajnc, N., Laina, R., Nordfjell, T., Triplat, M., Tolosana, E., 2022: Environmental Impacts of Boom-Corridor and Selectively Thinned Small-Diameter-Tree Forests. Sustainability 14(10): 6075. https://doi.org/10.3390/su14106075

de la Fuente, T., González-García, S., Athanassiadis, D., Nordfjell, T., 2017: Fuel consumption and GHG emissions of forest biomass supply chains in Northern Sweden: a comparison analysis between integrated and conventional supply chains. Scandinavian Journal of Forest Research 32(7): 568–581. https://doi.org/10.1080/02827581.2016.1259424

Del Giudice, A., Scarfone, A., Santangelo, E., Latterini, F., Stefanoni, W., 2024: Modelling the productivity and economic feasibility for bioenergy production in a Mediterranean oak coppice. Drewno Prace Naukowe, Doniesienia, Komunikaty 67(213): 192178. http://dx.doi.org/10.53502/wood-192178

Đuka, A., Magagnotti, N., Simonetti, M., Stampfer, K., Pavelić, N., Spinelli, R., Papa, I., Bade, C., Borz, Stelian A., Lindroos, O., Lundbäck, M., Mederski, P.S., Bembenek, M., Mionetto, N., Erler, J., 2024: Technodiversity. Croatian journal of forest engineering 45(2): 445–454. https://doi.org/10.5552/crojfe.2024.2364

Englund, M., Rossander, M., Kärnell, S., Zackrisson, M., Ågren, K., Ericsson, L., 2022: Concepts of energy efficient electrified CTL forestry machines. In: Book of Abstracts. 55 international symposium on forestry mechanization (FORMEC) & 7 forest engineering conference (FEC) »Improving access to sustainable forest materials in a resource-constrained world«, September 20–22, 190 p.

Fox, J., Weisberg, S., Adler, D., Bates, D., Baud-Bovy, G., Ellison, S., Firth, D., Friendly, M., Gorjanc, G., Graves, S., 2012: Package »car.» Vienna: R Foundation for Statistical Computing 16(332): 333.

Gasparini, P., Tabacchi, G., 2011: L'Inventario Nazionale delle Foreste e dei serbatoi forestali di Carbonio INFC 2005. Secondo inventario forestale nazionale italiano. Metodi e risultati (in Italian). Edagricole-Il Sole 24 ore, Bologna, Treviso, Venezia.

Ghaffariyan, M.R., Apolit, R., Kuehmaier, M., 2018: A Short Review of Fuel Consumption Rates of Whole Tree and Cut-To-Length Timber Harvesting Methods. Current Investigations in Agriculture and Current Research 5(2): 603–606. https://doi.org/10.32474/CIACR.2018.05.000209

Kärhä, K., Eliasson, L., Kühmaier, M., Spinelli, R., 2024: Fuel Consumption and CO2 Emissions in Fully Mechanized Cut-to-Length (CTL) Harvesting Operations of Industrial Roundwood: A Review. Current Forestry Reports 10(4): 255–272. https://doi.org/10.1007/s40725-024-00219-3

Kärhä, K., Haavikko, H., Kääriäinen, H., Palander, T., Eliasson, L., Roininen, K., 2023: Fossil-fuel consumption and CO2eq emissions of cut-to-length industrial roundwood logging operations in Finland. European Journal of Forest Research 142(3): 547–563. https://doi.org/10.1007/s10342-023-01541-4

Klein, D., Wolf, C., Schulz, C., Weber-Blaschke, G., 2015: 20 years of life cycle assessment (LCA) in the forestry sector: state of the art and a methodical proposal for the LCA of forest production. International Journal of Life Cycle Assessment 20(4): 556–575. https://doi.org/10.1007/s11367-015-0847-1

Klvac, R., Fischer, R., Skoupy, A., 2012: Energy use and emissions from the medium distance cableway system operation phase. Croatian Journal of Forest Engineering 33(1): 79–88.

Kühmaier, M., Kral, I., Kanzian, C., 2022: Greenhouse Gas Emissions of the Forest Supply Chain in Austria in the Year 2018. Sustainability 14(2): 792. https://doi.org/10.3390/su14020792

Laina, R., Tolosana, E., Ambrosio, Y., 2013: Productivity and cost of biomass harvesting for energy production in coppice natural stands of Quercus pyrenaica Willd. in central Spain. Biomass & Bioenergy 56: 221–229. https://doi.org/10.1016/j.biombioe.2013.04.016

Lajunen, A., Sainio, P., Laurila, L., Pippuri-Mäkeläinen, J., Tammi, K., 2018: Overview of Powertrain Electrification and Future Scenarios for Non-Road Mobile Machinery. Energies 11(5): 1184. https://doi.org/10.3390/en11051184

Landekić, M., Martinić, I., Bakarić, M., Pentek, T., Poršinsky, T., Šporčić, M., 2018: Current state and improvement potential of forestry workers training in Croatia. Croatian Journal of Forest Engineering 39(2): 289–298.

Latterini, F., Dyderski, M.K., Horodecki, P., Venanzi, R., Picchio, R., Jagodziński, A.M., 2024a: Evaluating small‐scale harvesting disturbance to the forest soil in Mediterranean beech high forests. Land Degradation and Development 35(15): 4419–4427. https://doi.org/10.1002/ldr.5228

Latterini, F., Horodecki, P., Dyderski, M.K., Scarfone, A., Venanzi, R., Picchio, R., Proto, A.R., Jagodziński, A.M., 2024b: Mediterranean beech forests: Thinning and ground-based skidding are found to alter microarthropod biodiversity with no effect on litter decomposition rate. Forest Ecology and Management 569: 122160. https://doi.org/10.1016/j.foreco.2024.122160

Latterini, F., Jagodziński, A.M., Horodecki, P., Stefanoni, W., Venanzi, R., Picchio, R., 2023a: The State of the Art of Forest Operations in Beech Stands of Europe and Western Asia. Forests 14(2): 318. https://doi.org/10.3390/f14020318

Latterini, F., Stefanoni, W., Venanzi, R., Tocci, D., Picchio, R., 2022a: GIS-AHP Approach in Forest Logging Planning to Apply Sustainable Forest Operations. Forests 13(3): 484. https://doi.org/10.3390/f13030484

Latterini, F., Venanzi, R., Picchio, R., Jagodziński, A.M., 2023b: Short-term physicochemical and biological impacts on soil after forest logging in Mediterranean broadleaf forests: 15 years of field studies summarized by a data synthesis under the meta-analytic framework. Forestry 96(4): 547–560. https://doi.org/10.1093/forestry/cpac060

Latterini, F., Venanzi, R., Stefanoni, W., Sperandio, G., Suardi, A., Civitarese, V., Picchio, R., 2022b: Work Productivity, Costs and Environmental Impacts of Two Thinning Methods in Italian Beech High Forests. Sustainability 14(18): 11414. https://doi.org/10.3390/su141811414

Lenth, R., Singmann, H., Love, J., Buerkner, P., Herve, M., 2019: Emmeans: estimated marginal means, aka least-squares means (Version 1.3. 4).

Leszczyński, K., 2023: Efficiency and Ability of Employees to Work in Relation to Timber Quality and Structural Ageing. Drewno Prace Naukowe, Doniesienia, Komunikaty 66(212): 177425. http://dx.doi.org/10.53502/wood-177425

Liepiņš, K., Lazdiņš, A., Liepiņš, J., Prindulis, U., 2015: Productivity and Cost-Effectiveness of Mechanized and Motor-Manual Harvesting of Grey Alder (Alnus incana (L.) Moench): A Case Study in Latvia. Small-scale Forestry 14(4): 493–506. https://doi.org/10.1007/s11842-015-9302-1

Louis, L.T., Kizha, A.R., Daigneault, A., Han, H.S., Weiskittel, A., 2022: Factors affecting operational cost and productivity of ground-based timber harvesting machines: a meta-analysis. Current Forestry Reports 8(1): 38–54. https://doi.org/10.1007/s40725-021-00156-5

Lu, X., Li, Y., Wang, H., Singh, B.P., Hu, S., Luo, Y., Li, J., Xiao, Y., Cai, X., Li, Y., 2019: Responses of soil greenhouse gas emissions to different application rates of biochar in a subtropical Chinese chestnut plantation. Agricultural and Forest Meteorology 271: 168–179. https://doi.org/10.1016/j.agrformet.2019.03.001

Magagnotti, N., Spinelli, R., Kärhä, K., Mederski, P.S., 2021: Multi-tree cut-to-length harvesting of short-rotation poplar plantations. European Journal of Forest Research 140(2): 345–354. https://doi.org/10.1007/s10342-020-01335-y

Marcolin, E., Manetti, M.C., Pelleri, F., Conedera, M., Pezzatti, G.B., Lingua, E., Pividori, M., 2020: Seed regeneration of sweet chestnut (Castanea sativa Miller) under different coppicing approaches. Forest Ecology and Management 472: 118273. https://doi.org/10.1016/j.foreco.2020.118273

Mergl, V., Pandur, Z., Klepárník, J., Kopseak, H., Bačić, M., Šušnjar, M., 2021: Technical solutions of forest machine hybridization. Energies 14(10): 2793. https://doi.org/10.3390/en14102793

Marziliano, P.A., Tognetti, R., Mercuri, M., Labate, A., Lombardi, F., 2022: Balancing stand productivity and wood quality in chestnut coppices using chronosequence approach and productivity model. European Journal of Forest Research 141(6): 1059–1072. https://doi.org/10.1007/s10342-022-01488-y

Nordfjell, T., Athanassiadis, D., Talbot, B., 2003: Fuel Consumption In Forwarders. International Journal of Forest Engineering 14(2): 11–20. https://doi.org/10.1080/14942119.2003.10702474

Patrício, M.S., Nunes, L., Monteiro, M.L., 2020: Does the application of silvicultural management models drive the growth and stem quality of sweet chestnut coppices towards sustainability? New Forest 51(4): 615–630. https://doi.org/10.1007/s11056-019-09748-3

Picchio, R., Pignatti, G., Marchi, E., Latterini, F., Benanchi, M., Foderi, C., Venanzi, R., Verani, S., 2018: The Application of Two Approaches Using GIS Technology Implementation in Forest Road Network Planning in an Italian Mountain Setting. Forests 9(5): 277. https://doi.org/10.3390/f9050277

Poikela, A., Ovaskainen, H., 2022: Fuel efficiency of the Logset 8H GTE Hybrid -harvester. Available online at https://www.metsateho.fi/wp-content/uploads/Tuloskalvosarja-2022-02-EN-Fuel-efficiency-of-the-Logset-8H-GTE-Hybridharvester.pdf. Accessed on 12th November 2024. Metsäteho, Result Series 2-EN/2022

Prada, M., Bravo, F., Berdasco, L., Canga, E., Martínez-Alonso, C., 2016: Carbon sequestration for different management alternatives in sweet chestnut coppice in northern Spain. Journal of Cleaner Production 135: 1161–1169. https://doi.org/10.1016/j.jclepro.2016.07.041

Puchałka, R., Prislan, P., Klisz, M., Koprowski, M., Gričar, J., 2024: Tree-ring formation dynamics in Fagus sylvatica and Quercus petraea in a dry and a wet year. Dendrobiology 91: 1–15. https://doi.org/10.12657/denbio.091.001

R Development Core Team, 2023: R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing, Vienna Austria. Available online: http://www.r-project.org/ (accessed on 6th October 2023)

Schweier, J., Magagnotti, N., Labelle, E.R., Athanassiadis, D., 2019: Sustainability Impact Assessment of Forest Operations: a Review. Current Forestry Reports 5(3): 101–113. https://doi.org/10.1007/s40725-019-00091-6

Schweier, J., Spinelli, R., Magagnotti, N., Becker, G., 2015: Mechanized coppice harvesting with new small-scale feller-bunchers: Results from harvesting trials with newly manufactured felling heads in Italy. Biomass and Bioenergy 72: 85–94. https://doi.org/10.1016/j.biombioe.2014.11.013

Spinelli, R., Lombardini, C., Magagnotti, N., 2014: The effect of mechanization level and harvesting system on the thinning cost of Mediterranean softwood plantations. Silva Fennica 48(1): 1003. https://doi.org/10.14214/sf.1003

Spinelli, R., Magagnotti, N., Tuomasjukka, D., 2021: Rationalization of coppice management in Mediterranean Europe: the sustainability effects of changing product strategy and technology level. International Journal of Forest Engineering 32(1): 53–62. https://doi.org/10.1080/14942119.2021.1913710

Spinelli, R., Visser, R., 2008: Analyzing and Estimating Delays in Harvester Operations. International Journal of Forest Engineering 19(1): 36–41. https://doi.org/10.1080/14942119.2008.10702558

Spinelli, R., Visser, R.J.M., 2009: Analyzing and estimating delays in wood chipping operations. Biomass and Bioenergy 33(3): 429–433. https://doi.org/10.1016/j.biombioe.2008.08.003

Stoilov, S., Proto, A.R., Oslekov, D., Angelov, G., Papandrea, S.F., 2024: Forest operations using a combi–forwarder in deciduous forests. Small-scale Forestry 23(1): 25–40. https://doi.org/10.1007/s11842-023-09552-0

Verkerk, P.J., Costanza, R., Hetemäki, L., Kubiszewski, I., Leskinen, P., Nabuurs, G.J., Potočnik, J., Palahí, M., 2020: Climate-Smart Forestry: the missing link. Forest Policy and Economy 115: 102164. https://doi.org/10.1016/j.forpol.2020.102164

Weyrens, J.P., Therasme, O., Germain, R.H., 2022: Quantifying the Life Cycle Greenhouse Gas Emissions of a Mechanized Shelterwood Harvest Producing Both Sawtimber and Woodchips. Forests 13(1): 70. https://doi.org/10.3390/f13010070

Appendix

Table A1 Description of working cycle phases

|

Operation |

Phase |

Description |

|

Felling/processing |

Moving |

Began when the operator started traveling toward the next tree and ended when it reached the tree |

|

Cleaning |

Began with the removal of branches and ended when the tree was ready for felling |

|

|

Felling |

Started when the cutting process began and ended once the tree was fully detached and on the ground |

|

|

Processing |

Began when the operator started delimbing and bucking the felled tree and ended when the processed logs were laid aside |

|

|

Forwarding |

Travel unloaded |

Began when the forwarder moved toward the cutblock and ended upon arrival at the loading location |

|

Loading |

Started when the boom engaged the first log and ended after the last log was placed on the bunk |

|

|

Travel unloaded |

Started once the forwarder moved toward the landing site and ended upon arrival |

|

|

Unloading |

Began when the first log was lifted off the bunk and ended after the last log was placed in the pile at the landing site |

|

|

Travel unloaded |

Began when the skidder moved from the landing toward the cutblock and ended upon reaching the first bunch |

|

|

Skidding |

Bunching |

Started with the first catch of logs and ended after the skidder completed log accumulation |

|

Travel unloaded |

Began when the skidder started moving toward the landing with logs and ended upon arrival |

|

|

Piling |

Began with log release at the landing and ended after the last log was placed in the pile at the landing site |

© 2025 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Prof. Rodolfo Picchio, PhD *

e-mail: r.picchio@unitus.it

Prof. Rachele Venanzi, PhD

e-mail: venanzi@unitus.it

University of Tuscia

Department of Agricultural and Forest Sciences

Via San Camillo de Lellis

01100 Viterbo

ITALY

Latterini Francesco, PhD

e-mail:

latterini@man.poznan.pl

Institute of Dendrology, Polish Academy of Sciences

Parkowa 5

62-035 Kórnik

POLAND

* Corresponding author

Received: January 14, 2025

Accepted: September 03, 2025

Original scientific paper

10