Productivity and Efficiency of Extracting Small-Sized Eucalyptus Logs by Farm Tractors with Backhoe Grapples in Thailand Short-Rotation Forestry

doi: https://doi.org/10.5552/crojfe.2026.3605

volume: 47, issue: 1

pp: 13

- Author(s):

-

- Kaakkurivaara, Tomi

- Kaakkurivaara Nopparat

- Borz Stelian Alexandru

- Article category:

- Original scientific paper

- Keywords:

- plantation forestry, operational planning, performance, models, simulation, time consumption

Abstract

HTML

Identifying effective methods for harvesting wood in short-rotation planted forests has recently become challenging, especially when trying to balance differing perspectives on the issue. In addition, practice in such forests may be highly variable from one place to another, and models are required to better understand the effectiveness of planted forest management and to make better decisions. A simulation experiment was setup in this study to understand how the productive performance of farm tractors, which is a common technical option in Thailand, is affected when extracting small-sized eucalyptus payloads sourced by very short cycles. Two tractors (hereafter T1 and T2) of different class size and fitted with backhoe grapples were selected and monitored via GNSS. Operational events were extracted from GNSS data, and were characterized by their speed, while payload size was estimated based on manual measurement done in the field. Then, simulations were carried out to see how moving speed and payload size may affect the productive performance as a function of extraction distance. Significant differences (α=0.05) in speed and payload size led to substantial variations in performance as the extraction distance increased. For instance, the number of daily work cycles were similar for both machines in a distance range of up to 100 m; daily production (m3), productivity (m3/h), and efficiency (h/m3), on the other hand, have shown important differences, with the higher size class T1 being more performant. Payload size and moving speed had a strong effect on efficiency, tripling the unit time for T2 at a distance of 1000 m. These findings have important consequences, at least for the local practice in South East Asia. Since these machines are frequently used interchangeably, the average extraction distance should be limited to 50 m, a scenario in which the differences in performance are the lowest. T1 maintains higher daily production and a greater number of work cycles at longer distances, highlighting the importance of choosing the appropriate tractor size for varying extraction distances in short-rotation eucalyptus forestry. Furthermore, the extraction distance should also be planned based on the performance of upstream and downstream processes, since the local practice makes use of motor-manual tree felling and cross-cutting, manual delimbing and bunching, and medium capacity trucks.

Productivity and Efficiency of Extracting Small-Sized Eucalyptus Logs by Farm Tractors with Backhoe Grapples in Thailand Short-Rotation Forestry

Tomi Kaakkurivaara, Nopparat Kaakkurivaara, Stelian Alexandru Bor

https://doi.org/10.5552/crojfe.2026.3605

Abstract

Identifying effective methods for harvesting wood in short-rotation planted forests has recently become challenging, especially when trying to balance differing perspectives on the issue. In addition, practice in such forests may be highly variable from one place to another, and models are required to better understand the effectiveness of planted forest management and to make better decisions. A simulation experiment was setup in this study to understand how the productive performance of farm tractors, which is a common technical option in Thailand, is affected when extracting small-sized eucalyptus payloads sourced by very short cycles. Two tractors (hereafter T1 and T2) of different class size and fitted with backhoe grapples were selected and monitored via GNSS. Operational events were extracted from GNSS data, and were characterized by their speed, while payload size was estimated based on manual measurement done in the field. Then, simulations were carried out to see how moving speed and payload size may affect the productive performance as a function of extraction distance. Significant differences (α=0.05) in speed and payload size led to substantial variations in performance as the extraction distance increased. For instance, the number of daily work cycles were similar for both machines in a distance range of up to 100 m; daily production (m3), productivity (m3/h), and efficiency (h/m3), on the other hand, have shown important differences, with the higher size class T1 being more performant. Payload size and moving speed had a strong effect on efficiency, tripling the unit time for T2 at a distance of 1000 m. These findings have important consequences, at least for the local practice in South East Asia. Since these machines are frequently used interchangeably, the average extraction distance should be limited to 50 m, a scenario in which the differences in performance are the lowest. T1 maintains higher daily production and a greater number of work cycles at longer distances, highlighting the importance of choosing the appropriate tractor size for varying extraction distances in short-rotation eucalyptus forestry. Furthermore, the extraction distance should also be planned based on the performance of upstream and downstream processes, since the local practice makes use of motor-manual tree felling and cross-cutting, manual delimbing and bunching, and medium capacity trucks.

Keywords: plantation forestry, operational planning, performance, models, simulation, time consumption

1. Introduction

The plantation forests account for approximately 131 M ha of the global forest area (FAO 2020). The Eucalyptus plantations area covers about 25 M ha, with Thailand contributing around 1.8 M ha, which means that roughly 7% of the world's Eucalyptus plantations are located in Thailand (Martins et al. 2022, Haruthaithanasan 2016). The annual harvesting volume of Eucalyptus is approximately 16 M tonnes, while the local pulp and chips industry exports accounted for nearly one-third of this total in 2023 (Premashthira 2024). Due to Eucalyptus properties, fast growth, and short rotation time, Thailand is an important producer of pulp and paper in Southeast Asia (Woods et al. 2011). Very short-rotation Eucalyptus planted forests result in small-sized logs, as harvesting typically occurs when the trees are between five and eight years old in Southeast Asia (FAO 2009, Sein and Mitlöhner 2011, Nguyen and Youn 2012).

Manpower and animal assisted extraction remain common practices in Thailand, despite being labour-intensive, time consuming, and providing relatively low productivities (Kaakkurivaara and Kaakkurivaara 2018, Manavakun 2014). Recently, Thai forestry has implemented a wide range of machines for harvesting and transportation operations, with partly mechanized harvesting techniques gradually replacing the most labour-intensive methods. Three categories for forest mechanization were proposed by Harstela (1993): basic technology (e.g., chainsaws), intermediate technology (e.g., farm tractors), and advanced technology (e.g., forwarders). Selecting the most appropriate technology for timber harvesting depends on multiple criteria, such as productivity, costs, characteristics of the company, ecological conditions, and both environmental and socio-economic impacts. The harvesting systems vary depending on operating environments, whereas the most appropriate techniques are characterized by several factors: harvesting method, gross domestic production, social security rate, diesel price, and terrain steepness (Lundbäck et al. 2021). These factors have led to the widespread use of modified farm tractors for extraction in Thailand, as they offer a reasonable purchase price, accessible financing options, and a low-cost maintenance. Similar machine options are popular around the world and productivity studies have been conducted in various scenarios, where a trailer, a winch, or a skidding device is paired with a farm tractor (Spinelli et al. 2004, Brown et al. 2022, Öztürk et al. 2019). The technical modifications of farm tractors and design of their accessories are often tailored to local circumstances to meet the specific requirements for handling and maneuvering during timber extraction operations (Borz and Mititelu 2022, Cataldo et al. 2018, Kulak et al. 2023, Dudek and Janas 2022). In Thailand, two farm tractor based extraction methods are used under different conditions. For long logs, such as Teak and other valuable tree species, a skidding device is mounted on the rear hitch, while bucking is performed at a designated processing site (Borz et al. 2022). The other method involves a farm tractor equipped with a backhoe grapple, which lifts the logs off the ground and extracts them by carrying. This extraction method has two different technical implementations, both designed for extracting short logs e.g. Rubber tree and Eucalyptus. The short log length is the result of manual delimbing and stacking of logs after motor-manual felling, and it is typically a consequence of partly mechanized methods used to load the trucks, and length limitations of debarking machines at mill yards. The review study by Di Fulvio et al. (2024) on harvesting and extraction productivities and costs, did not identify any similar techniques used on industrial plantations in other parts of the world.

In general, the productivity of farm tractor-based extraction is primarily affected by payload size, hauling distance and slope gradient (Brown et al. 2022, Sessions 2007, Gilanipoor et al. 2012, Gülci et al. 2018). Due to generally larger tree sizes in plantation forestry, only a few studies have been published that correspond to similar circumstances in Thailand. Furthermore, productivity studies of extracting small-sized logs in short rotation plantations have been carried out using other types of farm tractor based extraction methods. The estimated productivities for coppice plantations (e.g. for poplar) were observed at 20.7 SMH-1 on tractor-based grapple skidding with a mean payload of one tonne, and a distance of 112 m; for Eucalyptus, productivity was estimated at 13.6 PMH-1 fresh tonnes and 9.5 SMH-1 fresh tonnes / for a tractor-trailer system used for forwarding with a payload of 7.3 tonnes and a distance of 174 m (Spinelli et al. 2020, Spinelli et al 2004). Productivity studies on short log extraction using the backhoe grapple method described above have not been conducted. Given this, it is important to study the productivity and efficiency of farm tractors equipped with a backhoe grapple for timber harvesting. Although this extraction method is commonly used in Thailand, Myanmar and Cambodia, it has potential for applicability in other geographical areas as well. The backhoe grapple method could be a valuable alternative for timber or woody biomass extraction in regions with similar conditions, such as eucalyptus, poplar, and willow plantations.

In this study, a simulation approach was chosen. The use of simulation studies in forest operations has gained popularity and acceptance for addressing questions related to productivity, efficiency, and fuel consumption (e.g., Borz et al. 2023, Kaakkurivaara et al. 2022, Forkuo et al. 2024). Simulation provides several advantages, one of which is that of predicting the impact of extraction distance on productivity, whereas the regression model based studies are often limited to covering results only up to maximum observed distance (Jourgholami 2014, Ghaffariyan et al. 2013, Behjou et al. 2008, Sabo and Poršinsky 2005). Therefore, simulation can help in understanding the system's behavior under varying operating conditions by utilizing simple mathematical models and statistical analysis. Difference between the definitions of a model and simulation are described by Banks (2009) so that simulation is a method used to observe the system's behavior, helping in better understanding the system's functions when changes occur within its operation boundaries.

The analysis of timber extraction using the backhoe grapple method in short rotation Eucalyptus plantations is an example that can be studied by simulation to reveal its potential. In additon to documenting the performance of this method, the management of the timber supply chain in Thailand could benefit from the results that provide reliable information, helping to develop and optimize the efficiency of the timber supply chain. Timber extraction method has a substantial influence on costs of the supply chain, as the share of costs for extraction are estimated to be about one third of the total cost of harvesting (Metsäteho 2006, Manavakun 2014) Therefore, the productivity of the extraction method is an important factor in determining the overall costs of timber harvesting.

The aim of this study was to estimate and simulate the productivity in small-sized log extraction operations by two types of backhoe grapples mounted on farm tractors. The study was based on work cycle measurements done in the field, combined with estimation of production. The objectives of the study were to:

identify the cycle-wise events for both tractors and their event-level speeds and shares, estimate mean volume and characteristics of the payloads

and identify the impact of extraction distance and payload on time consumption of extraction.

2. Materials and Methods

2.1 Location and of Study Site

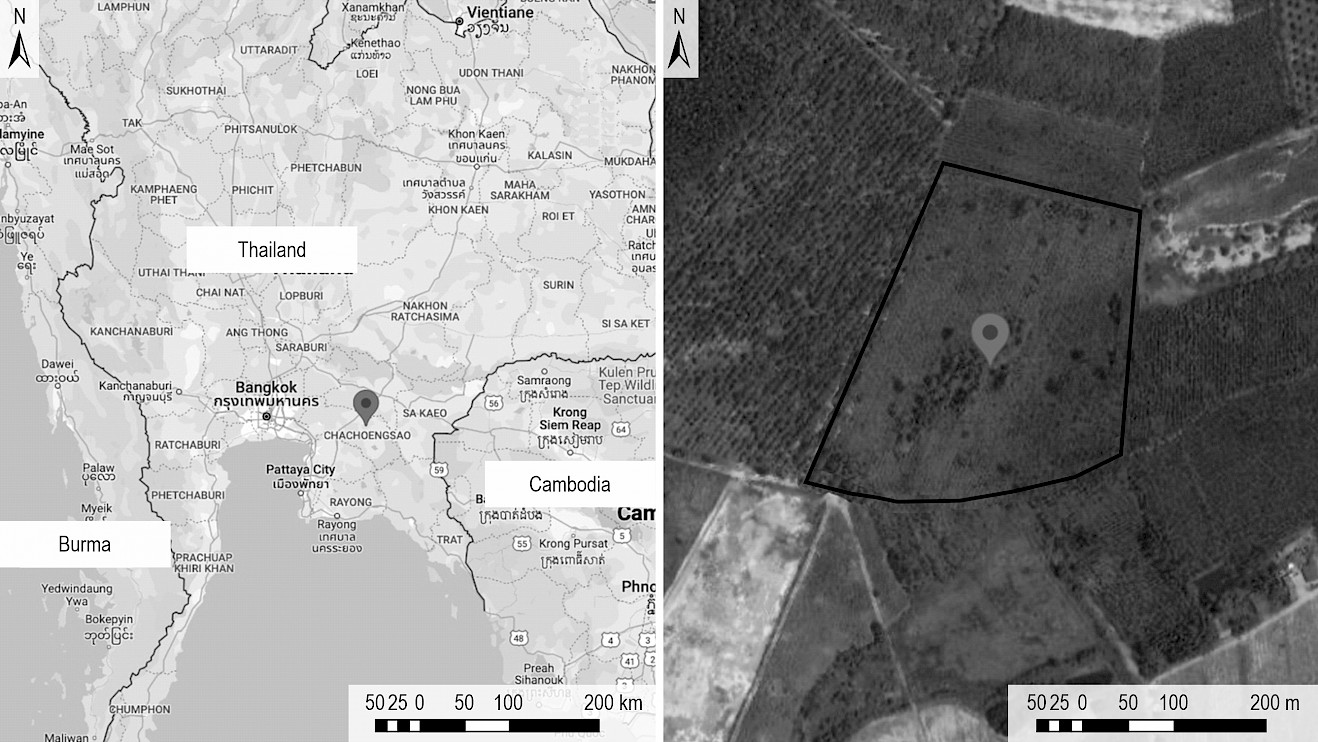

Data collection was carried out in the Chachoengsao province, Eastern Thailand in July 2023 (Fig. 1), in an Eucalyptus plantation located at approximately 13°40'08.1"N 101°35'59.7"E at an elevation of 36 m above sea level (Thailand topographic map 2024). The climate is subtropical in this region and data was collected during the dry season. The plantation was approximately five years old and it was coppiced with one to four stems per stump. The original planting density was approximately 1660 trees ha-1, which means that distances between stumps were two meters in a row and three meters between the rows in the logging area. This spacing between rows and trees is commonly used in Thailand. Due to coppice plantation management, operators avoided to damage stumps, to ensure vitality of stumps for the next rotation. The study area was located on a flat terrain with a sandy soil. The average tree size was of up to 0.02 m3/tree, wich means an estimated volume extracted per hectare of about 33 m3. The trees were harvested for the pulp industry, and the stems were crosscut into length of between two to three meters.

Fig. 1 Location of the study site in Thailand

2.2 Description of Machines and Work Organization

The study involved two farm tractors equipped with extraction devices, which had a different technical design and working techniques. The technical specifications of the tractors are presented in Table 1. In this study, these machines were named as T1 and T2 (Fig. 2). T1 was a medium size tractor, where driving direction had been changed to opposite. The main modifications were those of changing the transmission and vehicle controls to work in the opposite direction, to mount a hydraulic lifting device with a fixed grapple to work from back to front, and to add a counterweight for improved balance. The maximum opening of the grapple was 115 cm. T2 was a small size tractor, on which the rear hitch was used to mount a grapple that operates vertically. The grapple opening and closing function was hydraulically powered on the upper jaw, while the lower jaw was fixed, straight, and mounted horizontally. The opening dimension was 55 cm and jaw depth was 67 cm. The driving direction for T2 remained unchanged, but the loading operation had to be performed in reverse, whereas the T1 drove forward during loading work due to its modifications. Fig. 2 shows some examples of the machines under study.

Table 1 Technical information of tractors used in study

|

Parameter |

T1 |

T2 |

|

Make and model |

Ford 6610 |

Kubota L5018 |

|

Number of cylinders |

4 |

4 |

|

Displacement, L |

4.4 |

2.4 |

|

Net power, kW |

58.6 |

34.6 |

|

PTO power, kW |

53.7 |

28.7 |

|

Pump flow capacity, L/min |

36.8 |

29.4 |

|

Max torque, Nm |

297 |

155 |

|

Operating weight, kg |

3084 |

1490 |

|

Number of gears |

8–2 |

8–2 |

Fig. 2 Backhoe grapple tractors under study

For both, T1 and T2, the work was organized in a similar manner, as observed in the field. Each machine was operated by a single worker, and both operators had extensive experience in similar operations. The typical work cycle included the empty turn, covering the distance from the landing to the place at which the logs were loaded, loading the logs from the first bunch, followed by movement to the next bunch and loading, and continuing this process until a full payload was formed for extraction. Once loaded, the tractor returned to the landing and unloaded the logs onto the ground. In addition, maneuvers were taken to position the machine at the unloading place. The workers involved in the research were fully informed about the purpose, procedures, and intended outcomes of the study. Prior to their involvement, each participant provided informed consent, acknowledging their understanding and agreement to participate. The study protocol was designed to ensure transparency, voluntary participation, and respect for the rights and well-being of the workers.

2.3 Data Collection, Processing and Analysis

The data required by this study was collected through visual observation, GNSS data recording, video recording, and manual measurements. The purpose of visually observing the operations was to understand how the work was organized for the two machines under study, as well as to identify any significant differences in how the tasks were performed. Representative data was also captured through video recording and later analyzed in the office to characterize the organization of work. Handheld GNSS receivers (Garmin, GPSmap 62 stc, Garmin International Inc., Olathe, KS, USA) were placed on the cabs of the two tractors and set to record locations at a rate of one second. The instruments were installed on the machines at the beginning of work and removed at the end of operations. Visual observations in the field done by two researchers revealed a low variability in payload size for each tractor. To estimate the producton, the workers were asked to place aside five payloads for each machine. These payloads were randomly chosen and subjected to detailed manual measurements of the length and end diameters of each log, providing the necessary data data for simulating daily production, productivity and efficiency.

During the field observations, over 25,000 and 21,000 second-level GNSS locations were recorded for T1 and T2, respectively. These were saved on the internal memory of the used GNSS units, then they were retrieved as .GPX files and stored in a PC for further analysis. A visual analysis was carried out in Garmin Base-Camp software (Garmin International inc., Olathe, KS, USA). This was done synchronously with a database created in Microsoft Excel version 2013 (Microsoft, Redmont, WA, USA), where the GNSS data was imported from the Garmin Basecamp software and merged in chronological order. By visualizing interactively the geometry, speed, and heading of the machines in Garmin Basecamp canvas, it was possible to identify events such as moving empty, moving partly loaded, loading, moving fully loaded, maneuvering and other events, including delays. For simplicity, all movements of the machine, whether empty or fully loaded, were coded as »Moving« in the database. Movement between small bunches of logs, loading by accumulation, and other events related to other loading related activities were categorized and coded as »Collecting« in the database. All the locations that could be identified as maneuvers in the forest or at the landing were classified as »Maneuvers«. The remaining data, including potential delays or data that could not be clearly distinguished as an event from those mentioned above, was coded as »Other«. Starting and ending points of each event were documented in Garmin Basecamp by visualization, then the corresponding codes were given to these events in the Microsoft Excel database.

Using this coding system, GNSS speed was extracted for each event in Microsoft Excel and assumed to represent the operational speed for the specific locations associated with that event. Then, a statistical analysis workflow was run to check whether the speed data was normally distributed by the means of D'Agostino-Pearson test. In addition, the cycle-wise events were identified for both machines in the data sets and their durations were extracted to compute the mean duration for each machine. The mean volume of the payload for each tractor was estimated based on measuring every log length and diameters at both log ends (Smalian's formula) for all the payloads retained for analysis. Descriptive statistics of event-level speeds, share of the events in the two datasets, and the characteristics of the payloads, were reported as a first result of the study, supporting the simulations on the average cycle time, number of work cycles covered in a day, daily production, productivity, and efficiency.

Following the data normality checks, which was done by a Shapiro-Wilk test, both the payload size and event speed were compared using statistical comparison tests deemed appropriate for the type of data and its distribution. Since payload size data was found to follow a normal distribution, and the samples taken for the two tractors were paired, a paired t test for independent samples was used for comparison to check whether there were statistically significant differences. For the event speed data, since the assumtion of normal distribution was not checked, and the samples were not paired, a Mann-Whitney non-parametric test was used for comparison. All the tests performed assumed a confidence threshold of 95% (α=0.05).

2.4 Simulation of Operational Performance

The primary assumption for simulation was that the extraction distance would be the main factor affecting the performance, given that the forests studied were situated on flat terrain. In addition, the simulation was not run as a typical work-cycle based study, but instead considered the average conditions that could characterize a given forest plot, while using some cycle-level data. Therefore, a given plot can be characterized in terms of operational performance by its mean conditions in terms of extraction distance. This is frequently used in forest operations planning and it practically assumes that the wood to be extracted is concentrated in a point standing for the centroid of that plot. As the main factor of simulation, extraction distance was considered to be between 50 and 1000 m, with a step of 50 m, a work day was considered to last for eight hours. A legal break of 1 hour in that time was assumed to be taken by the workers during the working day, which led us to use seven hours in simulations. Simulations on average cycle time, number of cycles, daily production, productivity, and efficiency, were done in Microsoft Excel by implementing Eq. 1 to 6.

Where:

tcycle i average cycle time for a given condition in terms of extraction distance, i stands for the tractor under study (i=T1 or T2)

tin-out i average in-out time, accounting for the time spent to drive the machine from the landing to the first loading place and from the last loading place to the landing

tcollecting i average time spent in the »Collecting« event, computed based on the cycle-wise data

tmaneuvering i average time spent in maneuvers to return the machine, computed based on the average speed data of »Maneuvering« event and the typical maneuvering distance observed in the field, which was set at 10 m

tunloading i average time for unloading, which was set at 1 minute irrespective of the machine.

Where:

EDj average extraction distance, where j stands for the extraction distance step (j = 50 to 1000 m with a step of 50 m)

Sm stands for the average speed of »Moving« event.

Where:

ncycles number of work cycles.

Where:

Pdaily i production, tons/day

APLi avarage payload.

Where:

Phourly i productivity, tons/hour.

Where:

E Efficiency, hours/ton.

For convenience, time was computed in hours irrespective of category, daily production was computed in cubic meters, productivity in cubic meter per hour and efficiency in hours per cubic meter, all based on productive machine hours (PMH0). Some of these concepts were adapted from the work of Björheden et al. (1995). Data extraction, database creation and data processing were supported by Garmin BaseCamp and Microsoft Excel. Statistical analysis was carried out by the use of Real Statistics add-in, and visual components of the results were developed in Microsoft Excel. In comparisons, in this study we used conversion factors from cubic meters in fresh weight (Kaakkurivaara et al. 2024).

3. Results

3.1 Description of Data

The GNSS-speed datasets used for statistical analysis contained a number of 25,647 and 21,848 observations taken at one second for T1 and T2, respectively. The most dominant event, in terms of relative frequency, was »Other«, which accounted for 55 and 64% in T1 and T2 datasets, respectively. There were no important differences in the overall relative time consumption between T1 and T2 for the event »Moving«. The main differences were observed in the relative frequency of »Collecting« and »Maneuvering« events. »Collecting« accounted for 17 and 10%, while »Maneuvering« accounted for 7 and 4% in T1 and T2 datasets, respectively.

Table 2 summarizes the main descriptive statistics of the observed GNSS speed. None of the variables under study passed the normality test. Accordingly, the mean, median and standard deviation values are reported in Table 2 for comparison purposes. As shown, T1 was characterized by higher operational speeds, irrespective of the event under study. Machine moving recorded an average value of 5.4 km/h for T1, which was slightly higher than that of T2 (3.9 km/h). In addition, log collection, which included sub-events of moving and loading, was performed at a higher speed by T1 as opposed to T2, while maneuvering was done by both tractors at similar speed.

Based on the standard variation values, the highest speed variability was found in the »Other« and »Collecting« events, which may be explained by the fact that, for instance, »Other« contained full stops with a speed of 0 km/h, as well as driving at high speed outside the felling block to carry out tasks that were out of the study scope. »Collecting«, on the other hand, included low-speed movements and even full stops combined with movement at higher speeds between the bunches of logs, supporting the increased variability in speed as reported in Table 1.

Moving and maneuvering speeds, as reported in Table 2, were used for simulation of the average cycle time, number of work cycles, daily production, productivity and efficiency. For the »Collecting« event, the cycle level data was used to estimate the mean duration. Accordingly, it was of 139 seconds (0.039 hours) and 116 seconds (0.032 hours) for T1 and T2, respectively, reflecting also a lower time needed to form a payload for T2, which was consistent with the payload size of T2. Based on field observations, and having in mind that a suitable detection and extraction of machine unloading events was not possible from the GNSS data, unloading was assumed to take one minute (0.017 hours) irrespective of the machine used. This fixed value was further used in simulation.

Table 2 Summary statistics of event-based GNSS speed of T1 and T2

|

Event |

Speed of T1, km/h |

Speed of T2, km/h |

|

Moving |

5.4 (5.0) ± 1.23 |

3.9 (3.8) ± 1.18 |

|

Collecting |

1.6 (1.0) ± 1.59 |

0.9 (0.6) ± 0.97 |

|

Maneuvering |

2.6 (2.9) ± 1.38 |

2.1 (1.9) ± 1.02 |

|

Other |

0.9 (0.2) ± 1.31 |

0.4 (0.1) ± 1.25 |

|

1 None of the variables came from a normal distribution, and the event speed data was found to be statistically different between the two tractors by the Mann-Whitney test |

||

Measuring the cycle-wise payload of each machine was impractical given the characteristics of the payloads, which were composed of many low-sized logs, as reported in Table 3. Additionally, a full measurement of the production would have caused important interferences with the way of organizing the work.

Table 3 Number and share of observations on subjects, tasks, and job

|

Parameter |

T1 |

T2 |

|

Total number of measured logs |

469 |

217 |

|

Mean number of logs per payload |

94 |

43 |

|

Average length of measured logs, m |

2.6 ± 0.55 |

2.8 ± 0.47 |

|

Average diameter of measured logs, cm |

5.3 ± 2.33 |

5.6 ± 2.46 |

|

Mean volume of payload, m3 |

0.575 ± 0.09 |

0.310 ± 0.05 |

|

1 None of the variables used to estimate the payload volume came from a normal distribution. Payload volume was found to follow a normal distribution based on the results of Shapiro-Wilk test, and the mean values were statistically different according to the results of the t-test |

||

There was a low variability in payload size as observed in the field and reported in Table 3, which summarizes the descriptive statistics for a number of five payloads randomly chosen and measured in detail for each machine. As shown, the payload size of T2 in terms of number of logs was almost half that of T1, which was also the case of payload size measured as volume (Table 3). This occurs when log lengths (2.6 vs. 2.8 m) and log diameters (5.3 vs. 5.6 cm) in the payloads of both machines are comparable, with a low variability at least in terms of length (Table 2). The mean volumes of the payloads, as reported in Table 3 for T1 and T2, respectively, were used further in simulation to estimate the daily production, productivity and efficiency as a function of the extraction distance.

3.2 Results of Simulation

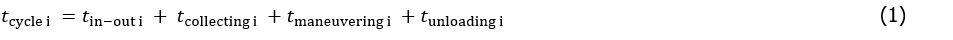

Simulations aimed to characterize the average cycle time, number of daily work cycles, daily production, productivity and efficiency for both machines. Fig. 3–5 summarize the simulation results for average extraction distances between 50 and 1000 m. It should be noted that the average extraction distance (ED) based on the field observed data was about 125 m, ranging from a couple of meters to about 250 m. Fig. 3 illustrates the effect of average extraction distance on the elemental time consumption categories, as well as on the average work cycle time. The emphasis here is on the variation of moving time (Tio), which is strongly related to extraction distance, and which depends on the machine speed in such events. It increased linearly as a function of average extraction distance, but to a less magnitude for T1 due to a higher moving speed. For the average conditions as observed in the study (ED=125 m), it accounted for about 0.050 and 0.055 hours for T1 and T2, respectively. It included the two-way (in and out) driving, and it had the strongest effect on the average work cycle time (ACT). Therefore, the moving speed of the machine, which may depend on its capability as well as the capabilities of the driver and work behavior, may significantly affect the cycle time.

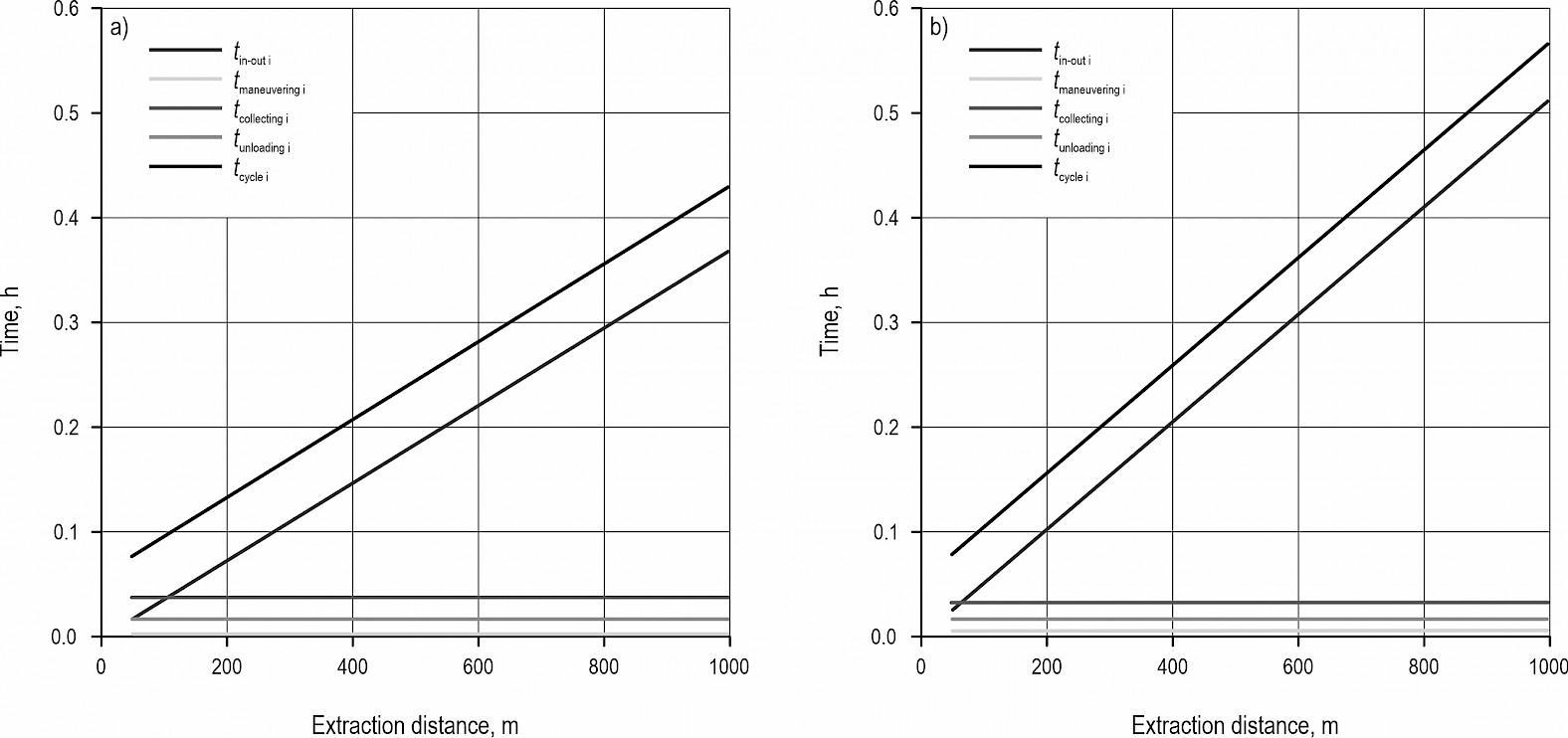

These findings have implications on the theoretical number of daily work cycles, as well as on the production, emphasizing both, the effect of moving speed and extraction distance on the simulated daily performance. Fig. 4 shows a comparison in terms of simulated work cycles and daily production for the two machines under study, by considering a working time of the shift of seven hours, as well as the mean size of the payloads. As shown, for short extraction distances, say 50 m, the effects in terms of number of work cycles is even. In other words, the moving speed and payload size do not cause important differences in terms of number of work cycles. These stay close in magnitude up to an average extraction distance of about 100 m, a point from which T1 increasingly outperforms T2 due to a higher moving speed. The highest differences appear at about the half of the extraction distance range selected for simulation (i.e., about 500 m) and then the differences start to decrease. In terms of daily production (Fig. 4b), the findings are quite different because the payload size brings an additional important effect. As shown, the daily production of T2 is almost half that of T1 for an extraction distance of 50 m. Even at a distance of 1000 m, there is a difference of about 5 m3 in the daily production of the two machines. Based on these findings, significant differences between the two machines are evident, primarily due to payload size, regardless of the extraction distance. To balance or increase production, the extraction distance should be shortened. In practice, operators often move trucks as close as possible to the operation site to reduce the extraction distance (Manavakun 2014).

Fig. 3 Description of simulated time (PMH0) categories for: (a) T1 and (b) T2: average cycle time (tcycle i), average in-out time (tin-out i), average maneuvering time (tmaneuvering i), average collecting time (tcollecting i), and average unloading time (tunloading i)

Fig. 4 Number of simulated work cycles and daily production for T1 and T2: (a) A comparison between T1 and T2 in terms of simulated work cycles, (b) A comparison between T1 and T2 in terms of daily production (m3) (PMH0)

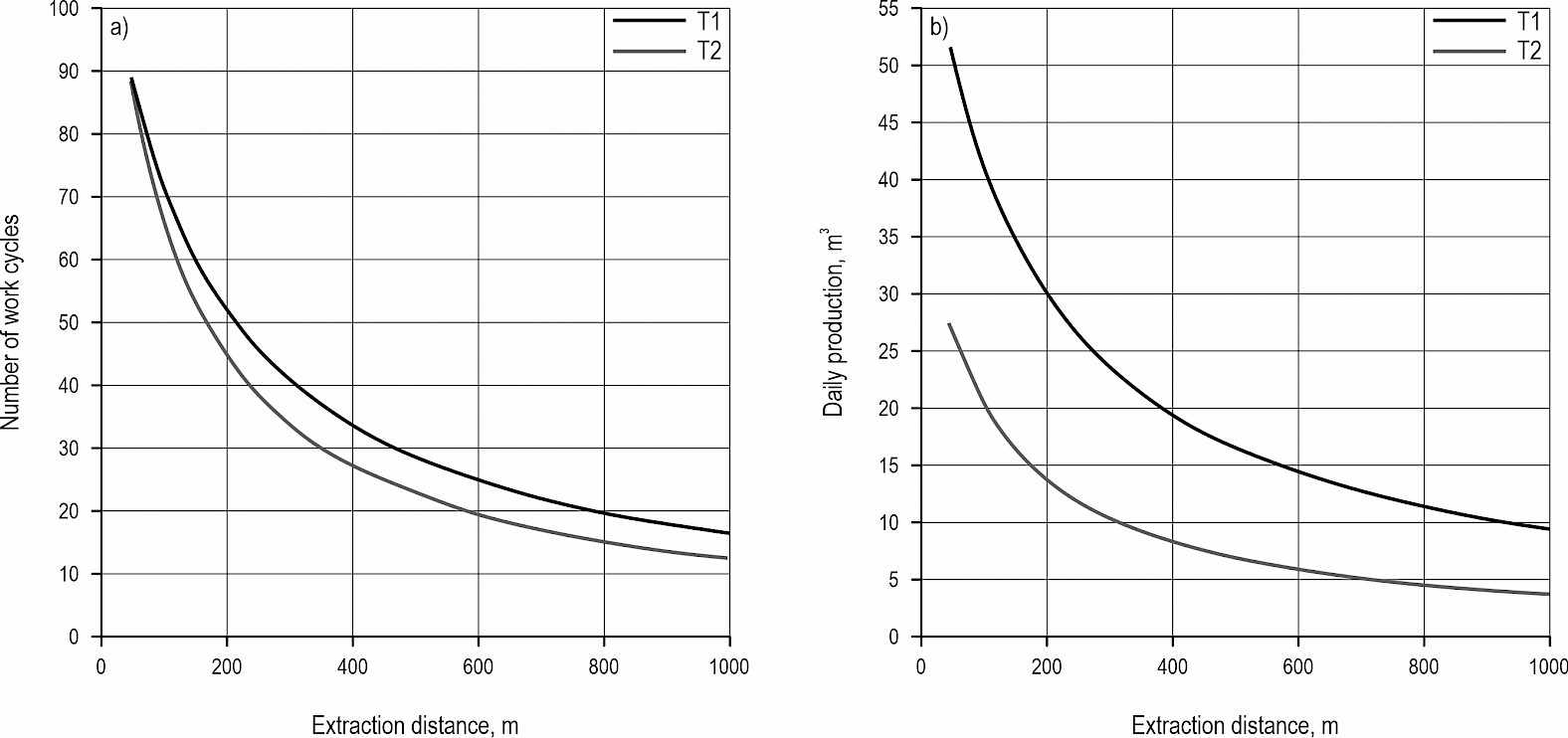

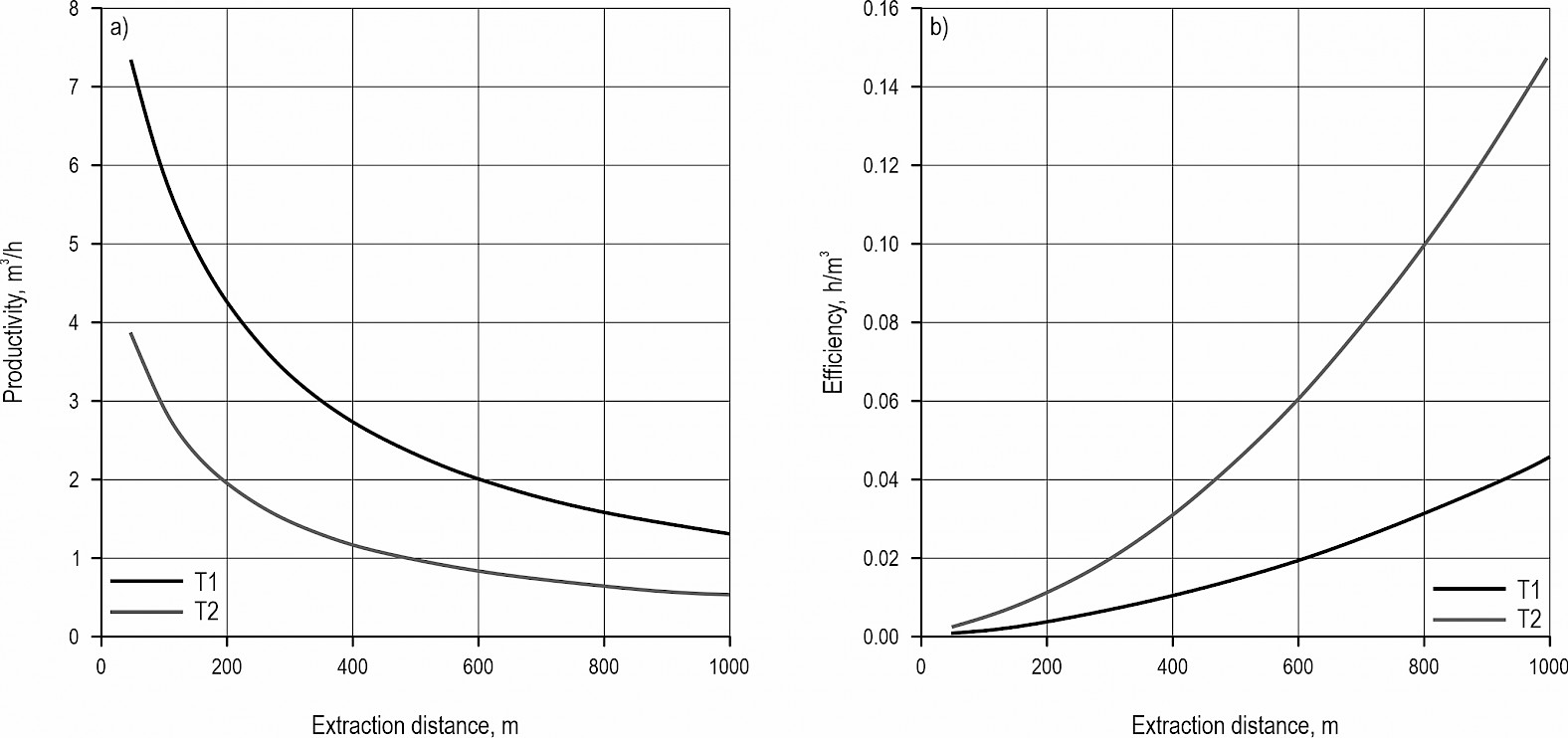

Last, but not least, Fig. 5 compares the two machines in terms of productivity and efficiency, providing figures that can be readily compared to those reported by other studies. The observed trends are consistent with those shown in Fig. 5, highlighting significant differences between T1 and T2. On the other hand, both productivity and efficiency were highly affected by the moving speed, payload size and extraction distance. For an extraction distance of 1000 m, which could be unrealistic for Thailand's practice, productivity drops to 0.17 and 0.22 of that which can be susbtained at a distance of 100 m. In addition, at a distance of around 100 m, T1 doubles the productivity that can be sustained by T2, a trend that has a higher magnitude as the extraction distance increases.

Fig. 5 Simulated productivity and efficiency of T1 and T2: (a) A comparison between T1 and T2 in terms of simulated productivity (m3/h), (b) A comparison between T1 and T2 in terms of efficiency (h/m3)

The differences in payload size and moving speed are more clearly reflected in the efficiency figures, as shown in Fig. 5b. While there are minimal differences at distances up to 100 m, efficiency sharply declines for T2 as unit time becomes increasingly higher relative to the extraction distance. This drop in efficiency can be explained by the important differences found in the moving speed and payload size, and at a distance of 1000 the unit time is tripled for T2.

4. Discussion

The studied eucalyptus harvesting method differs from many other typical eucalyptus cultivation regions due to tree size, with the exception of Southeast Asia and China, where similar silvicultural management and short-rotation periods are common due to high demand of raw material and significant capital commitment (Nguyen and Youn 2012, Engler et al. 2016, Hardiyanto et al. 2024). Techno-economic limitations in harvesting, transportation, and processing at pulp mills have resulted in shorter log lengths. In these circumstances, the studied extraction method has gained popularity as the initial step towards mechanizing harvesting operations, transitioning from a fully manual process where small logs are loaded directly from the ground onto a truck (Manavakun 2014, Nájera-Luna et al. 2023). Farm tractors equipped with backhoe grapples were studied in the logging area that represents typical eucalyptus plantation conditions in Thailand, in the terms of terrain, tree size, and the technical setup and use of extraction devices. The field study supported the simulation results and the use of models for future investigations to computing costs, planning harvesting operations, and facilitating in decision making.

The productivity studies in small-sized tree plantations have consistently highlighted the low extraction productivity compared to the logging operations in larger tree plantations (Ackerman et al. 2021). Despite technical solutions and effective working methods, this gap has not been fully bridged. However, exploring regionally common extraction methods can inspire new ideas and developments that can be adapted to similar harvesting conditions elsewhere. Our study provided initial insights into recorded productivity rates and simulation results across a wide range of extraction distances. The collected data revealed that the number of logs per payload and the payload volume were approximately double with T1 compared to T2, even though the average log length and diameter were slightly larger in T2 payloads. This difference highlighted the superior capacity of T1 grapple size. Furthermore, the recorded event speeds of T1 underlined the mobility of tractor type. Extraction distances affected the productivity of both machines especially the slower one - T2. Compared to other farm tractor-based extraction methods, such as the farm tractors with sulky or forest trailers (Spinelli and Magagnotti 2012, Forkuo et al. 2024), the moving speed was lower.

Simulation results showed competitiveness of T1 against T2 in terms of productivity and efficiency (PMH0). In Fig. 5a, T1 and T2 achieved 5.9 and 2.9 m3 h-1 within 100 m distance, and 4.3 and 2.0 m3 h-1 within 200 m distance, respectively. Twofold productivity level gap between T1 and T2 was a logical consequence of payload size and event speeds. Compared to other extraction methods in coppice plantations in other parts of the world, productivity levels were low. Productivities of T1 and T2 at a mean distance of 100 m were about one fourth and one seventh, respectively, when compared to grapple skidding of full tree poplars at a distance of 112 m (Spinelli et al. 2020). Additionally, productivites of T1 and T2 for a distance of 200 m were about one third and one seventh, respectively, when compared to forwarding eucalyptus logs by tractor-trailer system at a distance of 174 m (Spinelli et al. 2004). The latter study included logs cut to a length of two meters with a mean mass of 35 kg. Based on average log dimensions in our study, the log size was very small, approximately six and seven kilograms for T1 and T2, respectively. Hence, the log sizes were only one sixth and one fifth compared to those in the study of Spinelli et al. (2004). It can be stated that our study revealed a relatively good performance, particulrarly for T1, when the results were proportioned to the log size. Unfortunately, there are no suitable studies available to make comparisons for the same log volumes. In Fig. 4a, the number of daily work cycles were similar for both machines in a distance range of up to 100 m, after which the gap was increasing as a consequence of event speeds. Daily production data (Fig. 4b) showed about 41.5 and 20.6 m3 for T1 and T2, respectively, at an extraction distance of 100 m. The efficiency results of simulation (Fig. 5b) show a lower efficiency for T2, which occurred as the extraction distance increased. However, when taking into account the local operation environment, it can be seen that productivity rates of both machines can be considered to be sufficient for the local supply chain. Thai timber transportation can be described as a hot supply chain where logs are delivered to the refinery immediately (during the same day) as the payment is based on fresh tonnes. Accordingly, T1 daily production can provide a sufficient amount of timber for both ten-wheel truck and 3-axle trailer combination, whereas T2 can fulfill the ten-wheel truck cargo space, these being the most common vehicle types for Thai timber haulage. Additionally, the truck can reach the border of the logging area in common forest road conditions, which typically limits the extraction distance to 300 m.

Our study focused on simulating productivity, but for a comprehensive viewpoint it is important to discuss the machine costs and economic issues of both machines. When selecting a smaller and less powerful farm tractor type as a base machine, investment and fuel costs are naturally lower than with a bigger tractor in harvesting operations (Spinelli and Magagnotti 2012). This opens the opportunity to choose T2 when extraction distance stays short to achieve a good level of productivity, and when the utilization rate of new machine cannot be accurately predicted. On the other hand, T1 provides clearly higher productivity and efficiency in all distances and an additional extra capability of loading the logs into trucks. It is worth mentioning that these small-sized eucalyptus trees needed to be stacked by hand in the load space after being lifted by machine.

Further development of both machines, especially T2, should improve the capacity of backhoe grapple to increase the payload size since, in terms of powertrain and hydraulic system, the tractor itself seems to have the capacity to carry heavier payloads. Simulation based on collected data showed that the productivity of T1 and T2 would be approximately 1 m3 h-1 higher, if the payload sizes increased by 0.1 m3 within 100 m extraction distance. To improve the supply chain management, longer log lengths should be practiced and the rotations should be extended to increase log size, as these would have a positive impact on productivity rates (Spinelli et al. 2022). They would have a positive effect on the supply chain, seeing that timber trucks were waiting to get their daily load ready on the harvesting site. Particularly in Thai supply chain, timber trucks are subordinate to the outcome of harvesting operations without sufficient road side storage capacity.

Predictive models of productivity for the studied machines need further work to support decision and facilitate the management in Thai harvesting operations. Future studies should investigate productivity in upstream and downstream processes of the supply chain in Thai eucalyptus plantation forestry to detect bottlenecks. Understanding the efficiency of the whole supply chain in relation to the causal factors, including motor-manual harvesting methods, truck loading and transportation in local conditions, would enhance and create possibilities for improvement of the whole supply chain. Limitations of this study consist of the data collected from a single harvesting site and machine operator for each machine. Uncertainty was tackled by choosing the most typical harvesting condition and operators' adequate level of working experience. As these simulation results were computed as effective machine hours, it needs to be kept in mind that working on very hot and highly humid weather will lower the work efficiency since breaks are often needed. On the other hand, one may question the accuracy of speed derived from GNSS data, which may be an important point affecting the results of this study. However, in the conditions of clear sky and flat lands, GNSS data has been proven to be accurate in Thailand (Thari et al. 2022), which validates our apporach. In such conditions, GNSS speed typically resembles well the real operational speed, particluarly when events such as sharp acceleration or deceleration do not occur (Rahemi and Mosavi 2021), which was the case in our study. In addtion, previous studies working with older generations of GNSS handheld receivers have proven a high level of matching between GNNS and ground truth speed (Keskin and Say 2006). Based on these, the GNSS speed results of this study offer a fair representation of the pace of events observed under the conditions of the real working environment.

5. Conclusions

This study measured and simulated the performance in use of farm tractors equipped with backhoe grapples when operating with small-sized logs in eucalyptus plantation conditions. General models to predict the productivity of two commonly used machines were introduced. The results showed a remarkable difference between machines. T1 performed better at all distances by a higher speed coupled with a higher payload size, although T2 may have some advantages in certain local Thai conditions. Hourly production rates were low when compared directly against other studies carried out in coppice plantations, which was affected by the very small logs. Furthermore, the simulation models highlighted the impact of payload size and extraction distance on productivity and efficiency. The recommended use of T2 should be aimed at short distances only, while T1 can be seen suitable for both short and long extraction distances. The findings also provide novel information for operational planning under various extraction distances, supporting better decision making in Thai short-rotation forestry.

Acknowledgments

This research was funded by the Transilvania Fellowship for Postdoctoral Research/Young Re-searchers at the Transilvania University of Brasov, Romania. The authors would like to thank Chayanee Ketkaew and Surapit Homnan for their active involvement in the field data collection activity, and Mr. Songran for making the field study possible. Special thanks are addressed to Mr. Kitipong Tangkit.

6. References

Ackerman, S.A., Talbot, B., Astrup, R., 2021: The effect of tree and harvester size on productivity and harvester investment decisions. Int J For Eng. 33(1): 22–32. https://doi.org/10.1080/14942119.2021.1981046

Banks, C.M., 2009: What is modeling and simulation? In Book Principles of modeling and simulation – A multidisciplinary approach, Sokolowski, J.A., Banks C.M., Eds.; John Wiley & Sons Inc.: Hoboken, NJ, USA, 259 p.

Behjou, F.K., Majnounnian, B., Namiranian, M., Dvořák, J., 2008: Time study and skidding capacity of the wheeled skidder Timberjack 450C in Caspian forests. J For Sci. 54(4): 183–188.

Björheden, R., Apel, K., Shiba, M., Thompson, M., 1995: IUFRO Forest Work Study Nomenclature. Swedish University of Agricultural Science, Department of Operational Efficiency: Garpenberg, Sweden.

Borz, S.A., Mititelu, V-B., 2022: Productivity and fuel consumption in skidding roundwood on flat terrains by a Zetor farm tractor in group shelterwood cutting of mixed oak forests. Forests 13(8): 1294. https://doi.org/10.3390/f13081294

Borz, S.A., Mariş, A.-C., Kaakkurivaara, N., 2023: Performance of skidding operations in low-access and low-intensity timber removals: a simulation of productivity and fuel consumption in mature forests. Forests 14(2): 265. https://doi.org/10.3390/f14020265

Brown, R.O., Oliveira-Nascimento, K.A., Robert, R.C.G., DeArmond, D., 2022: Wood extraction performance with a farm tractor in a mountainous region of Brazil: cycle time, productivity and costs of two different work crews. South For. 84(2): 136–147. https://doi.org/10.2989/20702620.2022.2078251

Cataldo, M.F., Proto, A.R., Macrì, G., Zimbalatti, G., 2020: Evaluation of different wood harvesting systems in typical Mediterranean small-scale forest: a Southern Italian case study. Ann silvic res. 45(1): 1–11. http://dx.doi.org/10.12899/asr-1883

Di Fulvio, F., Acuna, M., Ackerman, P., Ackerman, S., Spinelli, R., Abbas, D., Kaakkurivaara, N., Sánchez-García, S., Guerra, S.P.S., 2024: Benchmarking operational conditions, productivity, and costs of harvesting from industrial plantations in different global regions. Int J For Eng. 35(2): 225–250. https://doi.org/10.1080/14942119.2023.2296789

Dudek, T., Janas, D., 2022: The productivity and the costs forwarding wood of a farm tractor with a trailer in late thinning and cutting in gaps of forests. Forests 13(8): 1309. https://doi.org/10.3390/f13081309

Engler, B., Becker, G., Hoffmann, S., 2016: Process mechanization models for improved eucalyptus plantation management in southern China based on the analysis of currently applied semi-mechanized harvesting operations. Biomass Bioenergy. 87: 96–106. https://doi.org/10.1016/j.biombioe.2016.02.021

FAO, 2009: Asia-Pacific forestry sector outlook study II: Thailand forestry outlook study. Working Paper No. APFSOS II/WP/2009/22, Bangkok, Thailand.

FAO, 2020: Global forest resources assessment 2020; Key findings; Food and Agriculture Organization of the United Nations, Rome, Italy; 16 p. https://doi.org/10.4060/ca8753en

Forkuo, G.O., Marcu, M.V., Iordache, E., Borz, S.A., 2024: Timber Extraction by Farm Tractors in Low-Removal-Intensity Continuous Cover Forestry: A Simulation of Operational Performance and Fuel Consumption. Forests 15(8): 1422. https://doi.org/10.3390/f15081422

Ghaffariyan, M.R., Naghdi, R., Ghajar, I., Nikooy, M., 2013: Time prediction models and cost evaluation of cut-to-length (CTL) harvesting method in a mountainous forest. Small-scale For. 12(2): 181–192. https://doi.org/10.1007/s11842-012-9204-4

Gilanipoor, N., Najafi, A., Heshmat Alvaezin, S.M., 2012: Productivity and cost of farm tractor skidding. J For Sci. 58(1): 21–26. https://doi.org/10.17221/4804-JFS

Gülci, S., Halit Büyüksakallı, H., Taş, İ., Akay, A.E., 2018: Productivity analysis of timber skidding operation with farm tractor. Eur J Forest Eng. 4(1): 26–32. https://doi.org/10.33904/ejfe.428397

Hardiyanto, E.B., Inail, M.A., Nambiar, S., Mendham, D.S., 2024: Sustaining plantation forest productivity in Sumatra over three decades: from acacias to eucalypts. Forest Ecol Manag. 553: 121613. https://doi.org/10.1016/j.foreco.2023.121613

Jourgholami, M., 2014: Productivity and cost of a small-scale timber forwarding system using farm tractors in the Hyrcanian forest, northern Iran. Taiwan J For Sci. 29(2): 103–116.

Lundbäck, M., Häggström, C., Nordfjell, T., 2021: Worldwide trends in methods for harvesting and extracting industrial roundwood. Int J For Eng. 32(3): 202–215. https://doi.org/10.1080/14942119.2021.1906617

Haruthaithanasan, M., 2016: Eucalyptus plantation management in Thailand. In: Proceedings of the 11th Biennial Short Rotation Woody Crops Operations Working Group Conference, Florida, USA, 11–13 October.

Harstela, P., 1993: Forest work science and technology, part I. Silva Carelica 25. University of Joensuu, Faculty of Forestry. Joensuu, Finland.

Kaakkurivaara, N., Kaakkurivaara, T., 2018: Productivity and cost analysis of three timber extraction methods on steep terrain in Thailand. Croat J For Eng 39(2): 213–221.

Kaakkurivaara, N., Kaakkurivaara, T., Ketkaew, C., Sakulya, T., Borz, S.A., 2022: Modelling productivity in extraction operations by simulations based on GNSS documented data: an example from skidding teak wood in Thailand. Bull Transilv Univ Bras. Ser II. 15(2): 13–32. https://doi.org/10.31926/but.fwiafe.2022.15.64.2.2

Kaakkurivaara, T., Korpunen, H., Kaakkurivaara, N., 2024: Mobile app for eucalyptus bucking—value chain optimization for smallholders. Small-scale For. 23(2): 239–255. https://doi.org/10.1007/s11842-024-09563-5

Keskin, M., Say, S.M., 2006: Feasibility of low-cost GPS receivers for ground speed measurement. Comput Electron Agric. 54(1): 36–43. https://doi.org/10.1016/j.compag.2006.07.001

Kulak, D., Szewczyk, G., Stańczykiewicz, A., 2023: Productivity and working time structure of timber forwarding in flatland thinned pine stand with the use of farm tractors. Croat J For Eng. 44(1): 57–67. https://doi.org/10.5552/crojfe.2023.1656

Manavakun, N., 2014: Harvesting operations in eucalyptus plantations in Thailand, Dissertationes Forestales 177. Academic dissertation, University of Helsinki, Helsinki, Finland, 28 May.

Martins, F.B., Benassi, R.B., Torres, R.R., Brito Neto, F.A., 2022: Impacts of 1.5 °C and 2 °C global warming on Eucalyptus plantations in South America. Sci Total Environ. 825: 153820. https://doi.org/10.1016/j.scitotenv.2022.153820

Metsäteho, 2006: Puunkorjuu ja kaukokuljetus vuonna 2005 [Harvesting and long-distance transportation on 2005]. Metsätehon katsaus nro 19, Metsäteho OY, Helsinki, Finland.

Nájera-Luna, J.A., Méndez-González, J., Corral-Rivas, S., Hernández, F.J., 2023: Productivity of manual loading system of logs in El Salto, Durango, México. Revista Chapingo Serie Ciencias Forestales Y Del Ambiente 29(2): 119–131. https://doi.org/10.5154/r.rchscfa.2022.06.042

Nguyen, H-D., Youn, Y-C., 2012: Optimum harvesting time and clone choices for eucalyptus growers in Vietnam. For Policy Econ. 15: 60–69. https://doi.org/10.1016/j.forpol.2011.09.011

Premashthira, A., Tangkit, K., Lamaisri, W., Kaakkurivaara, N., Na Takuathung, C., Neimsuwan, T., Jumwong, N., Meunpong, P., Kaakkurivaara, T., 2024: Analyzing the eucalyptus timber value chain in Thailand: profit distribution and opportunities for improvement. Forests 15(6): 1047. https://doi.org/10.3390/f15061047

Real Statistics Using Excel. Available online: https://www.real-statistics.com (accessed 4 July 2024).

Sabo, A., Poršinsky, T., 2005: Skidding of fir roundwood by Timberjack 240C from selective forests of Gorski Kotar. Croat J For Eng. 26(1): 13–27.

Sein, C.C., Mitlöhner, R., 2011: Eucalyptus urophylla S.T. Blake ecology and silviculture in Vietnam. Center for International Forestry Research. CIFOR, Bogor, Indonesia.

Sessions, J., 2007: Harvesting Operation in the Tropics. Springer, Germany.

Spinelli, R., Kováč, B., Heger, P., Heilig, D., Heil, B., Kovács, G., Magagnotti, N., 2022: The effect of target log length on log recovery and harvesting cost: the example of short-rotation poplar plantations. Forests 13(5): 669. https://doi.org/10.3390/f13050669

Spinelli, R., Magagnotti, N., Lombardini, C., 2020: Low-investment fully mechanized harvesting of short-rotation poplar (Populus spp.) plantations. Forests 11(5): 502. https://doi.org/10.3390/f11050502

Spinelli, R., Owende, P.M.O., Ward, S.M., Tornero, M., 2004: Comparison of short-wood forwarding systems used in Iberia. Silva Fenn. 38: 85–94.

Thailand topographic map. Available online: https://en-gb.topographic-map.com/map-63pz4/Thailand/ (accessed 19 July 2024).

Thari, P., Kriengkraiwasin S., Satirapod, C., 2022: Evaluating of GNSS positioning from satellite-based augmentation systems in Thailand. Eng Appl Sci Res. 49(2): 209–217.

Woods, K., Barney, K., Canby, K., 2011: Baseline study 5, Thailand: overview of forest law enforcement, governance and trade. Forest Trends for FLEGT Asia Regional Programme, 1–64.

Öztürk, T., Varsak, M., Bilici, E., 2019: Evaluating productivity and cycle time of skidding method with farm tractors in Bigadic forest enterprice directorate in Turkey. Eur J Forest Eng. 5(2): 77–82. https://doi.org/10.33904/ejfe.655241

© 2025 by the authors. Submitted for possible open access publication under the

terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Authors' addresses:

Tomi Kaakkurivaara, PhD

e-mail: tomi.kaakkurivaara@unitbv.ro

Prof. Stelian Alexandru Borz, PhD *

e-mail: stelian.borz@unitbv.ro

Transilvania University of Braşov

Faculty of Silviculture and Forest Engineering

Department of Forest Engineering

Forest Management Planning and Terrestrial Measurements

Şirul Beethoven 1

500123, Braşov

ROMANIA

Tomi Kaakkurivaara, PhD

e-mail: ffortkk@ku.ac.th

Assoc. prof. Nopparat Kaakkurivaara, PhD

e-mail: ffornrm@ku.ac.th

Kasetsart University

Faculty of Forestry

Department of Forest Engineering

50 Ngamwongwan Rd., Chatuchak

10900 Bangkok

THAILAND

* Corresponding author

Received: August 26, 2024

Accepted: March 19, 2025

Original scientific paper

13