Productivity, Costs and Residual Stand Damage of Timber Harvesting Methods in Scots Pine Stands with Extended Distance Between Skid Trails

doi: https://doi.org/10.5552/crojfe.2026.4081

volume: 47, issue: 1

pp: 18

- Author(s):

-

- Jakob Maximilian

- Cremer Tobias

- Mederski Piotr S.

- Berendt Ferréol

- Article category:

- Original scientific paper

- Keywords:

- Pinus sylvestris, forest operation, semi-mechanized timber harvesting, strip roads

Abstract

HTML

In forest operations, economic advantages can be obtained by increasing the distance between the skid trails. This protects soil by reducing the compacted area, while at the same time increasing the productive timber ground area. These advantages are offset by disadvantages, as fully mechanized timber harvesting is not possible and motor-manual felling is required for the areas that cannot be reached by the harvester. This in turn reduces work safety and increases the workload and personnel requirements, possibly leading to higher timber harvesting costs.

To analyze the consequences of an extended skid trail distance, a timber harvest under real conditions was carried out in north-eastern Germany in the fall of 2023. In a 72-year-old Scots pine (Pinus sylvestris, L.) stand with an area of 23.2 ha, 692 m³ of wood was harvested in a thinning operation. Three different timber harvesting methods with extended skid trail distances of approx. 40 m (ES) were investigated and compared to a fully mechanized system with conventional skid trail distances of approx. 20 m (CS) in a time study with a total of 150 recorded hours. Following the harvest, the residual stand damage was also recorded.

The timber harvesting methods with ES had higher timber harvesting costs than the method with CS, although there are major differences between the three semi-mechanized timber harvesting systems: The productivity of the harvester increases as the number of passes by the harvester decreases (from 13.87 to 14.09 to 15.99 m³/PMH15). Looking at the forwarder productivity, it is higher in ES than in CS. Finally, the costs of the harvesting systems ranged between 29.18 €/m³ for CS to 30.40, 32.41, 34.56 €/m³, respectively, for ES. There is no significant difference in the residual stand damage across the methods. The productivity of semi-mechanized timber harvesting methods can be improved if the motor-manual felling is carried out before the harvester is used and if the trees are not winched with a cable tractor.

Productivity, Costs and Residual Stand Damage of Timber Harvesting Methods in Scots Pine Stands with Extended Distance Between Skid Trails

Maximilian Jakob, Tobias Cremer, Piotr Mederski, Ferréol Berendt

https://doi.org/10.5552/crojfe.2026.4081

Abstract

In forest operations, economic advantages can be obtained by increasing the distance between the skid trails. This protects soil by reducing the compacted area, while at the same time increasing the productive timber ground area. These advantages are offset by disadvantages, as fully mechanized timber harvesting is not possible and motor-manual felling is required for the areas that cannot be reached by the harvester. This in turn reduces work safety and increases the workload and personnel requirements, possibly leading to higher timber harvesting costs.

To analyze the consequences of an extended skid trail distance, a timber harvest under real conditions was carried out in north-eastern Germany in the fall of 2023. In a 72-year-old Scots pine (Pinus sylvestris, L.) stand with an area of 23.2 ha, 692 m³ of wood was harvested in a thinning operation. Three different timber harvesting methods with extended skid trail distances of approx. 40 m (ES) were investigated and compared to a fully mechanized system with conventional skid trail distances of approx. 20 m (CS) in a time study with a total of 150 recorded hours. Following the harvest, the residual stand damage was also recorded.

The timber harvesting methods with ES had higher timber harvesting costs than the method with CS, although there are major differences between the three semi-mechanized timber harvesting systems: The productivity of the harvester increases as the number of passes by the harvester decreases (from 13.87 to 14.09 to 15.99 m³/PMH15). Looking at the forwarder productivity, it is higher in ES than in CS. Finally, the costs of the harvesting systems ranged between 29.18 €/m³ for CS to 30.40, 32.41, 34.56 €/m³, respectively, for ES. There is no significant difference in the residual stand damage across the methods. The productivity of semi-mechanized timber harvesting methods can be improved if the motor-manual felling is carried out before the harvester is used and if the trees are not winched with a cable tractor.

Keywords: Pinus sylvestris, forest operation, semi-mechanized timber harvesting, strip roads

1. Introduction

Scots pine (Pinus sylvestris, L.) is the most common tree species in Germany, with Scots pine-dominated forests covering 2.4 million hectares across the country. The species is particularly prevelant in Brandenburg (BMEL 2024a). Currently, the Scots pine, larch (Larix decidua, Mill.) and strobe pine (Pinus strobus, L.) species group accounts for 16.3% (11.5 million m³ in 2023) of all timber felled in Germany (BMEL 2024c). In Brandenburg, pine and larch account for 83.2% (3.8 million m³ in 2023) of all timber felled (Amt für Statistik Berlin-Brandenburg 2024). The framework conditions for timber harvesting in north-east Germany as well as in neighboring Poland are changing due to climate change (MLUK 2023, Benisiewicz et al. 2024, BMEL 2024b, Wessely et al. 2024) and changing political and societal demands on the forest. Ecosystem services such as carbon sequestration, water storage and filtration are playing an increasingly important role alongside timber production in forest management (Bösch et al. 2018, Ibisch and Blumröder 2020, Grunewald et al. 2023). This has an impact on timber harvesting because harvesting methods have to be further developed to meet these demands (Marchi et al. 2018).

For soil protection reasons, several German state forest administrations regulate their skid trail spacings to an average distance of more than 20 m. For example, the state forests in Bavaria have a permanent skid trail network with an average distance of 30 m between two skid trails (Baysf 2010). Moreover, 1.2 million hectares of forest are FSC-certified in Germany (FSC 2024b). According to the German FSC standard, the share of the skid trail area in the productive timber ground area should not exceed 13.5% in the medium term and 10% in the long term (FSC 2024a). However, it must be noted that, given the partial canopy over skid trails from edge trees, the skid trail area actually used by the forestry workers does not translate into an equivalent area of lossed productive woodland. In practice, this often leads to average skid trail spacings of 30 m or 40 m, with a skid trail width of 4 m (FVA 2003, Landesforstbetrieb Brandenburg (Lfb) 2023, FSC 2024a, 2024b). Advantages are seen in improved soil protection due to a smaller compacted skid trail area (Cambi et al. 2015) and increased overall stock and growth of the stand (Wächter 2021). Because of human-induced climate change, the frequency of droughts is increasing (IPCC 2023). As less compacted soil area in the forest can increase water storage capacity (Cambi et al. 2015), extending skid trail spacings may increase the drought resilience of forests. Due to future climatic conditions, timber harvesting operations will face additional constraints (Berendt et al. 2017). Moreover, the authors stated that the »growing awareness of forest soil protection may induce major technical changes for harvesting and extraction machines«. Therefore, there is a need to adapt and optimize the timber harvest methods accordingly.

Fully mechanized timber harvesting with a conventional skid trail (CS) distance of about 20 m is used worldwide (Lundbäck et al. 2021) and has already been well studied in terms of productivity and costs (Mederski 2006, Ghaffariyan and Brown 2013, Vusić et al. 2013, Ackerman et al. 2014, Spinelli et al. 2014, Proto et al. 2018). Although attempts are being made to develop corresponding machines with a very large boom reach (KWF 2023), it is not currently possible to use fully mechanized timber harvesting in combination with an extended skid trail (ES) spacing of about 40 m. As the boom reach of the harvester is too short to reach all trees, the trees outside the boom reach of the harvester must be felled motor-manually in the midfield (Mederski 2006, Berendt et al. 2020b). Following that, the trees can be winched by e.g. a mini forestry crawler or a cable tractor to the skid trail (Berendt et al. 2018). The distance of the winching process can be reduced by pulling the trees with the crown towards the skid trail. This could increase the productivity of the process while also reducing damage to the remaining trees as compared to when the trees are pulled with their bottoms towards the skid trail (Meng 1978, Nill 2011). Such semi-mechanized harvesting systems need furher research into the different circumstances and techniques (Lenz 2017). For example, study results from beech stands (Borchert et al. 2024) cannot simply be transferred to pine stands. It was shown by Mederski (2006) for pine stands with a DBH of 20 cm and 22 cm that the timber harvesting costs can be lower with extended skid trail spacing (ES) compared to conventional skid trail spacing (CS). This is due to the higher productivity of harvesters and forwarders as well as the shorter distances that must be driven. However, these results are not consistent with other studies and depend on the labour costs associated with motor-manual felling. In other studies, the timber harvesting costs are found to be higher for ES than for CS (Berendt et al. 2018, Mederski et al. 2018, Wächter 2021, Hennek 2022).

The trees in the midfield can be felled by chainsaw before the harvester fells the trees within its boom reach, meaning that the harvester only has to pass once. However, in that situation, motor-manual felling is rather challenging because: i) the skid trails are more difficult to identify without prior travel, and ii) more dense forest stands hamper felling in optimal direction towards the skid trail. As an alternative, the trees can be motor-manually felled after the harvester has cut the trees within its boom reach, meaning that the harvester has to pass twice (Mederski et al. 2018).

When trees are felled motor-manually with chainsaw, these trees can be winched to the skid trail by a winch or by horses. While this can increase harvester productivity, the overall process is significantly more expensive than without winchning (Lenz 2017). Magagnotti and Spinelli (2011) have shown that integrating horse bunching with tractor skidding can be more cost-effective than skidding directly with the tractor. The skidding with horses can cause less damage than a wire skidder (Wirth 2008). The motor manual felling and processing of the harvester can be optimized by special cutting operations (Forstliches Bildungszentrum Königsbronn 2009). The workload of winching logs with a mini forestry crawler (Berendt et al. 2018) can be reduced by replacing a steel cable with synthetic rope (Magagnotti and Spinelli 2012). An overview of the different methods is given by Ghaffariyan (2010).

Given that the residual stand damage caused during the timber harvest is an important economic factor (Borz et al. 2023), it should be included in the comparison of ES and CS. Various studies have investigated how to capture tree damage (Palander et al. 2018, Kizha et al. 2021). It has been shown by Behrendt (2010) that in order to achieve sufficient accuracy, at least 5–10 % of the available area must be recorded. The quantification of bark damage can be carried out more quickly with a variable sample circle radius with a 10-tree sample than with a fixed sample size (Richter 2019). It has been shown by Nill (2011) that the proportion of trees damaged by logging is considerable and that trees on the edge of skid trails in particular are often damaged. According to BMEL (2024a), 6.7% of all trees in Germany are damaged by timber harvesting. Fully mechanized timber harvesting can also cause damage in broadleaved stands with the percentage of damage being up to 39% (Ursić et al. 2022). The distance to the skid trail can have an influence on the frequency of damage (Thorpe et al. 2008, Nakou et al.2016).

Looking in more detail at Scots pine dominated stands with extended skid trail spacings, various timber harvesting methods are conceivable.

The following hypotheses were tested:

Semi-mechanized timber harvesting methods with ES are more expensive than fully mechanized timber harvesting methods due to the cost of motor manual felling, whereby the productivity of forwarder and possibly of harvester, too, is higher in ES than in CS due to a larger concentration of timber next to skid trail in ES

The productivity of motor-manual felling decreases if the trees are felled before the first pass by the harvester, but the total timber harvesting costs are lower in this case due to the higher overall productivity of the harvester

Damage to the remaining trees is dependent on the timber harvesting system, with a higher proportion of damaged trees in the fully mechanized system due to smaller skid trail distances. This was stated due to higher damage probability next to skid trails.

Therefore, the aim of this study was to analyze the productivity, costs and damage to residual trees of three different semi-mechanized (harvester-forwarder with participation of chainsaw felling) timber harvesting methods and to compare them with a fully mechanized system (harvester-forwarder only). As the harvester is the most expensive machine used in logging, it is particularly interesting to see how its productivity can be increased. For this reason, various parameters are examined to determine their influence on productivity.

2. Materials and Methods

2.1 Study Area

The study took place in a 72-year-old single-layer even-aged pine-dominated stand (Pinus sylvestris L.) in north-eastern Germany in the federal state of Brandenburg (N52.965°, E13.643°) (Fig. 1). A sample inventory prior to felling revealed a mean diameter at breast height (DBH) of 28.9 cm (5.0 cm standard deviation (SD)), a mean medium height of 23.1 m (3.2 m SD) and a stock volume of 400 m³/ha. The terrain was flat and the stands were homogeneous without strong undergrowth and with a negligible admixture of individual birch trees (Betula pendula Roth). On an area of 23.2 ha, a thinning operation took place in the fall of 2023 with a total wood harvest volume of 692 m³ (n=1815 trees), corresponding to a total withdrawal of 30 m³/ha.

Fig. 1 Location of the study area (left) and a picture of the pine stand (right)

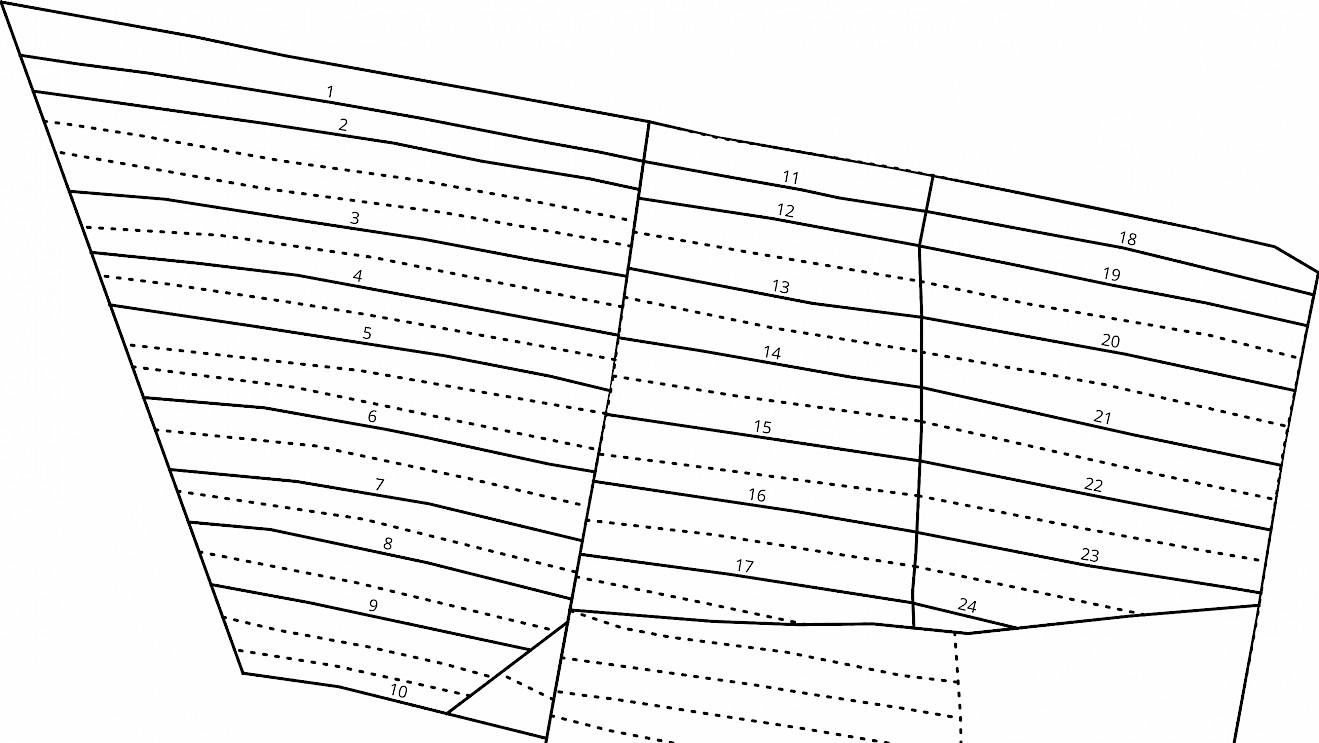

The existing skid trails were recorded with the GNSS device LogBuch+ (palos GmbH, Salzburg, Austria) prior to harvesting. About half of the existing skid trails are no longer used in order to comply with FSC regulations. The skid trails still in use are numbered from 1 to 24 with markings on the edge trees.

The location of the skid trails can be seen in Fig. 2, where both the abandoned (dashed lines) and the used skid trails (numbered lines) are shown.

Fig. 2 Design of the study area with used skid trails (solid line, numbered from 1 to 24) and abandoned skid trails (dashed line)

The average distance between skid trails was 22.3 m, 45.3 m, 43.2 m and 36.5 m in sections 1, 2, 3 and 4, respectively. After felling, the volume of the trees that were marked for harvesting but left on the site was recorded.

2.2 Examined Thinning Operations

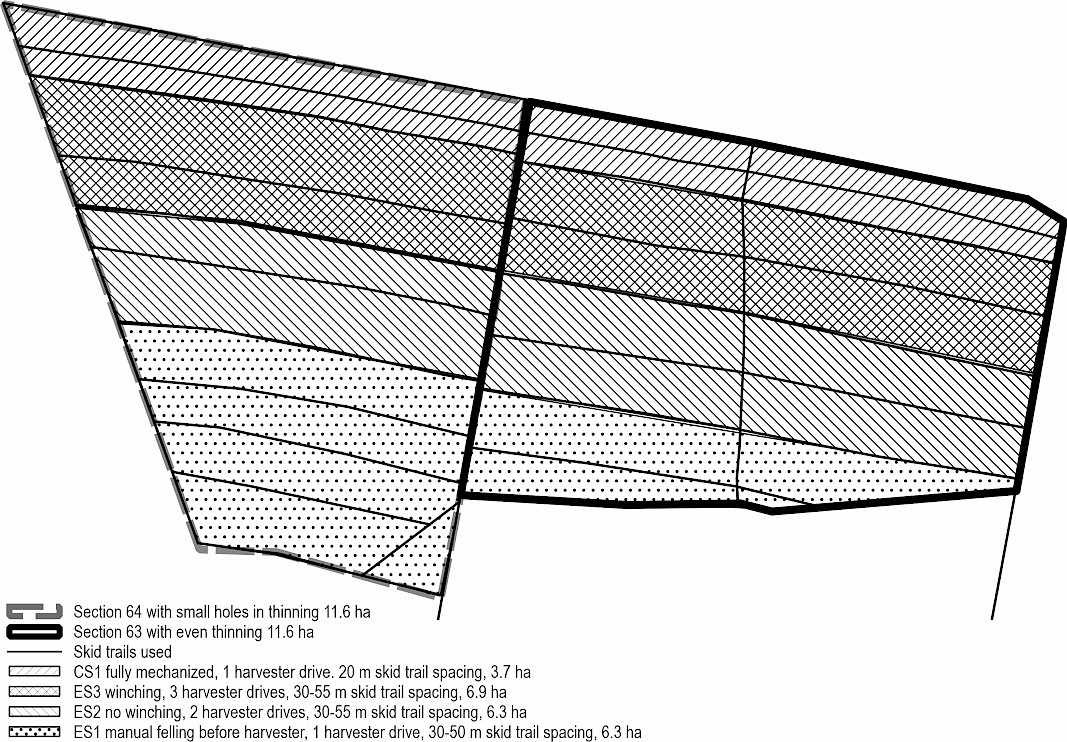

The trees to be removed were marked, with even thinning in section 63 and an attempt to increase the structure in section 64 with small holes. The even thinning in section 63 was essentially a negative selection, with no major gaps in the canopy. The small holes in section 64 were created in existing pine and birch rejuvenation. The aim is to give the existing small trees more light so that they grow faster and increase the structure of the forest. However, the same amount of wood was removed overall per hectare as with even thinning (Fig. 3).

Fig. 3 Experimental design of the study area. Used skid trails and 4 harvesting methods examined are shown

Four different timber harvesting methods were investigated: one with conventional skid trail distances of approx. 20 m (CS) and three with extended skid trail distances (ES). The designation of the methods indicates the number of passes of the harvester (CS1):

CS1 fully mechanized with one harvester pass: average skid trail spacing of 22.3 m; 1. felling and processing of all trees by harvester; 2. forwarding

ES3 winching with three harvester passes: average skid trail spacing of 45.3 m; 1. harvester felling and processing of all trees within reach of harvester boom; 2. motor-manual felling of the remaining trees in the middle field, all marked trees are felled; 3. harvester processing of the felled trees; 4. pre-winching by skidder with cable winch of trees that cannot be reached by harvester; 5. harvester processing of the trees pulled forward to the skid trails by the skidder; 6. forwarding

ES2 no winching with two harvester passes: average skid trail spacing of 43.2 m; 1. felling and processing of all trees within harvester boom reach; 2. motor-manual felling of the remaining trees in the middle field, all marked trees are felled; 3. processing of the felled trees by harvester, trees that the harvester cannot reach remain lying as deadwood; 4. forwarding

ES1 manual felling before harvester with 1 harvester pass: average skid trail spacing of 36.5 m; 1. motor-manual felling of the trees in the middle field, marked trees that are assessed by the forestry workers as not being able to be felled into the boom reach of the harvester are not felled; 2. felling and processing trees next to the strip road as well as processing only trees felled with chainsaw – all within boom reach of harvester, trees that the harvester cannot reach remain standing or lying as deadwood; 3. forwarding.

Timber harvesting was carried out using the machines and personnel of the state forest enterprise. The harvester was a Ponsse Bear manufactured in 2018 (current total of 9749 machine working hours) with a weight of 24.5 t, a boom reach of 8.6 m and a harvester head H7 with cutting diameter of 64 cm and a feed speed of 5 m/s. The forwarder was a Ponsse Buffalo built in 2018 (current total of 11,135 machine working hours) with a weight of 19.8 t and a boom reach of 7.8 m. The skidder used for the winching was a Welte W130 built in 2008 (current total of 11,017 machine working hours) with a weight of 6.5 t and equipped with a cable winch. The harvester and forwarder worked in two shifts with two different operators each. The winching with skidder was done by one person, while motor-manual felling was done by a group of three forestry workers. All test persons were experienced forest workers or machine operators with several years of experience.

All assortments were transported with a forwarder and stacked at the forest road. The timber volumes of the different methods were determined using the internal harvester measurement device.

2.3 Harvesting Volumes

A total of 1815 trees were processed by the harvester, of which 835 were motor-manually felled and 94 were winched with the skidder. The remaining marked trees had a volume of 63.55 m³ (Table 1).

Table 1 Processed and remaining marked trees. Percentages indicate the share of trees harvested

|

Method |

Area ha |

Trees processed by harvester n/ha |

Trees felled by chainsaw, n/ha |

Trees winched by skidder, n/ha |

Total harvest yield, m³/ha |

Remaining marked standing and lying trees, n/ha |

Remaining marked standing and lying trees, m³/ha |

Only lying remaining trees, n/ha |

Only lying remaining trees m³/ha |

|

CS1 |

3.7 |

77 |

0 (0%) |

0 |

31.45 |

13.8 |

4.9 (15.6%) |

0 |

0 (0%) |

|

ES3 |

6.9 |

82 |

42 (51%) |

14 (17%) |

30.36 |

0.4 |

0.1 (0.5%) |

0.3 |

0.1 (0.3%) |

|

ES2 |

6.3 |

77 |

44 (57%) |

0 |

28.95 |

7.9 |

2.9 (9.9%) |

8 |

2.8 (9.7%) |

|

ES1 |

6.3 |

76 |

43 (56%) |

0 |

29.24 |

10.6 |

4.2 (14.2%) |

1 |

0.5 (1.5%) |

2.4 Productivity and Costs

All working steps on the area were recorded with a time and motion study according to REFA (1998). The comparison of productivity and costs between the different timber harvesting methods was based on the effective working time PMH0 without interruptions and breaks (T1) measured during the time study by the respective method. The system boundaries are the skid trails of the respective timber harvesting methods: Working times that took place outside the skid trails, e.g. machine drives to the woodpile or the next skid trail could not be clearly assigned to a work cycle and were therefore measured for the respective work step as a whole (T2) and then added to the respective method as a percentage surcharge together with general times (T3). The general times (T3) are made up of set-up time (preparing for work), break travel time (way to break), distribution time, and recovery time. In the case of general times (T3), repairs and interruptions of up to 15 minutes are included when evaluating the times, which leads to a PMH15 productivity (Eriksson and Lindroos 2014, Johansson et al. 2024). Furthermore, meetings with the measuring personnel and unpaid breaks (breakfast, lunch, dinner) were not included in the time study. Timber volumes in this work are always given in m³ without bark, as measured by the harvester.

The total working time (T4, h) for the different working steps (harvester, forwarder, chainsaw, cable tractor) was calculated by:

Where:

T1 effective working time inside the system (system boundaries are skid trails) with ancillary activities

T2 effective working time outside the system (system boundaries are skid trails)

T3 general time.

The productivity (P, m³/PMH15) for the different working steps was calculated by:

Where:

V harvested wood volume in m³ under bark

The costs (C, €/m³) for the different working steps were calculated by:

Where:

Ch costs, €/PMH15

To calculate productivity and costs of manual felling and winching with the skidder, the volume of trees processed by these operations was calculated as a proportion of the total number of trees processed by the harvester in the respective methods:

Where:

Vm/w volume of trees that are motor-manually felled or winched by a skidder, m³

nm/w number of trees that are motor-manually felled or winched by a skidder

nh number of trees processed by harvester

Vh volume of trees processed by harvester, m³.

The costs for the machines included purchase price, maintenance costs, operating materials costs, operating costs, other company-related costs, and workers, including ancillary wage costs and relocation costs that were taken from the database KWF 2024 (Table 2). For the motor-manual felling, the machine costs refer to the chainsaw compensation as the forestry workers used their own chainsaws. The skidder was also used to pull down the trees that were left hanging in the crowns of other trees after motor-manual felling.

Table 2 Machine costs (acc. to KWF 2024)

|

Machine |

Machine costs €/h |

Wage costs €/h |

Total costs €/h |

|

Harvester |

188.44 |

44.60 |

233.04 |

|

Forwarder |

109.02 |

44.60 |

153.62 |

|

Motor-manual felling |

10.30 |

38.50 |

48.80 |

|

Skidder with cable winch |

93.50 |

45.00 |

138.50 |

As the two harvester operators and the three forestry workers in the motor-manual felling worked with different productivities and since their working time was not evenly distributed across all timber harvesting methods, the performance of the workers was interpolated with the number of processed trees. For all work steps not directly related to a tree (e.g. ancillary activities) the interpolation is not possible. However, these are added afterwards with the supplement percentage:

Where:

T1i effective working time inside the system without ancillary activities interpolated

T2 effective working time outside the system

T3 general time

Ta ancillary activities inside the system

T4i total working time interpolated.

For the interpolated effective working time within the system without ancillary activities, the average time of the various workers per tree in different processes is taken and multiplied by half (harvester) or a third (chainsaw) of the total number of trees processed or felled in the respective process, and added together. This theoretically assumes that each worker processed the same number of trees in each method:

Where:

T1ih harvester effective working time inside the system without ancillary activities interpolated

T1ic chainsaw effective working time inside the system without ancillary activities interpolated

na number of processed trees by harvester in the respective method

TpA1,2,3 effective working time inside the system without ancillary activities for working persons 1,2, 3.

2.5 Modelling Harvester Productivity

A multiple linear regression was performed to analyze the significance of the parameters »operator«, »timber« »harvesting method«, »work with or without daylight«, »management approach«, »harvesting volume«, »skid trail slope«, »type of tree« and »skid trail spacing« on harvester productivity. A level of α=0.05 was set for the significance. The evaluation was carried out at the cycle level. One cycle was defined as the sum of the two working steps: i) driving and ii) processing.

Table 3 shows the eight parameters examined for their influence on harvester productivity.

Table 3 Analyzed parameters for modelling harvester productivity

|

Parameter |

Values |

|

Operator |

1, 2 |

|

Timber harvesting method |

1, 2, 3, 4 |

|

Work during night (n) or day (d), sunrise and sunset as limit |

n, d |

|

Management approach, even thinning in section 63 (e) or small holes in section 64 (ue) |

e, ue |

|

Harvesting volume |

m³ ha-1 |

|

Skid trail slope |

°degree |

|

Type of trees: standing (s), chainsaw felled (c), winched (w) |

s, c, w |

|

Skid trail spacing |

m meter |

All analyses were performed using R Statistical Software (R Foundation for Statistical Computing 2023). The harvester working steps were divided into driving on the skid trail including movement of the boom and processing the trees (Appendix 1). The homogeneity of the variances was checked with a Levene test (Brown and Forsythe 1974) and the normal distribution was verified using the Anderson-Darling test (Anderson and Darling 1952). The univariate analyses Wilcox-Test (Bauer 1972), Kruskal-Wallis-Test(Hollander and Wolfe 1973), Dunn-Test (Dunn 1961) and Spearman-Test up (Best and Roberts 1975) were used to check which of the parameters had a significant influence on productivity. The outliers were identified via the mean absolute deviation from the median and their effects minimized using the S-estimator (Yohai et al.1991).

2.6 Damage

After felling, the damages to the remaining trees were recorded with a random sample inventory at 268 measuring points in a 25 m grid on the five nearest trees. A total of 1335 trees were examined for damage. A tree was considered damaged only if: i) the wound size was 10 cm² or more, and ii) the wound depth reached the cambium (Meng 1978). Furthermore, the distance of damaged trees to the edge of the nearest skid trail was measured with a tape measure. A chi-square test (Christensen et al. 2019) was used to check whether the damage percentages differed significantly between the different wood harvesting methods.

The complete tables of the time study, timber harvest damage and remaining trees are published and can be found under the heading data availability at the end of the document.

3. Results

3.1 Productivity

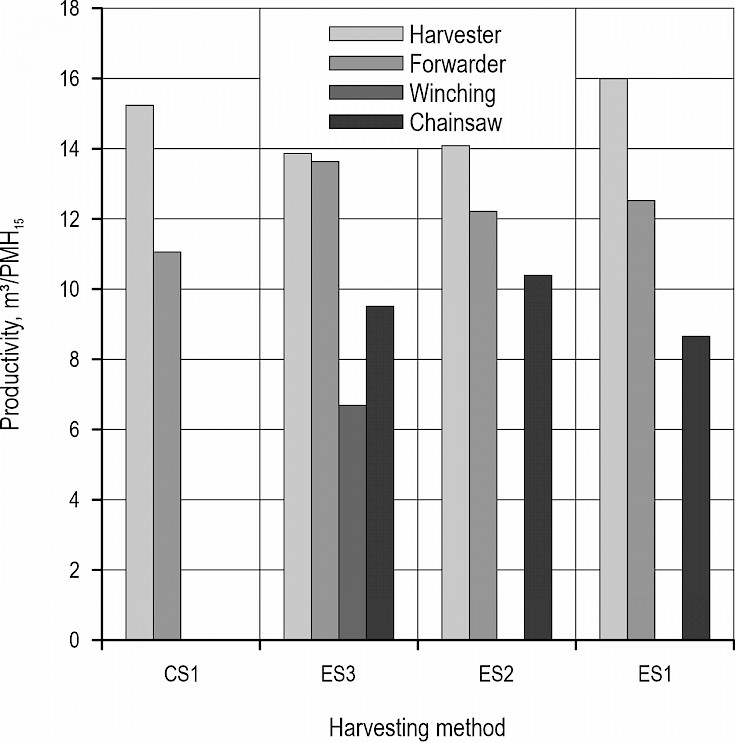

Productivity of the harvester in the ES methods increased as the number of harvester passes decreased (Fig. 4). While productivity in the ES3 (13.87 m³/PMH15, 3 harvester passes) and ES2 (14.09 m³/PMH15, 2 harvester passes) methods was below that of CS1 (15.24 m³/PMH15, 1 harvester pass), the harvester performance in ES1 exceeded that in CS1 at 15.99 m³/PMH15. For the forwarder, productivity in all three ES methods was higher at 12.21–13.63 m³/PMH15 than in CS1 at 11.06 m³/PMH15. For chainsaw felling, on the other hand, the performance in ES1, where felling was carried out before the harvester, was lower (8.66 m³/PMH15) than in ES3 (9.51 m³/PMH15) and ES2 (10.39 m³/PMH15), where felling was carried out after the harvester. The working step of winching occurred only in ES3 with a productivity of 6.69 m³/PMH15 (Fig. 4).

Fig. 4 Productivity of various working steps in different timber harvesting methods

3.2 Costs

The harvesting costs of the four methods examined showed that CS1 had the lowest harvesting costs with 29.18 €/m³, followed by ES1 (30.40 €/m³), ES2 (32.41 €/m³) and ES3 (34.56 €/m³), respectively (Table 4). When comparing ES3 and ES2 (chainsaw felling after harvester) with ES1 (chainsaw felling before harvester), it is noticeable that in ES1 the felling costs were higher (6.35 €/m³ compared to 5.74–5.98 €/m³), but the harvester costs were lower (14.58 €/m³ compared to 16.54-16.81 €/m³). Overall, ES1 is considerably cheaper than ES3 and ES2. The productivity of the harvester in the three ES methods increased as the number of passes decreased due to shorter distances. For the forwarder, productivity was higher in the ES methods compared to CS1 (Fig. 4). On the other hand, it must be considered that the average skid trail spacings of 36.5 m in ES1 were lower than in ES3 (43.2 m) and ES2 (36.5 m) due to inclined surface cuts.

Table 4 Costs of different working steps for the amount of wood processed by these working steps

|

Working step |

CS1 |

ES3 |

ES2 |

ES1 |

|

Harvester costs, €/m³ |

15.29 |

16.81 |

16.54 |

14.58 |

|

Winching costs, €/m³ |

– |

20.70 |

– |

– |

|

Chainsaw felling costs, €/m³ |

– |

5.98 |

5.74 |

6.35 |

|

Forwarder costs, €/m³ |

13.89 |

11.27 |

12.58 |

12.27 |

|

Total costs, €/m³ |

29.18 |

34.56 |

32.41 |

30.40 |

3.3 Modelling Harvester Productivity

The multiple linear regression showed that the parameters thinning and skid trail spacing were not significant and the harvest volume, with an estimate of –0.5275, only had a small influence and, with a Pr(>|t|) of 0.012739, was significant but not highly significant. Without these non-significant parameters, the multiple linear regression yielded the results for the residuals (Table 5).

Table 5 Residual results of multiple linear regression for harvester

|

Minimum |

Limit of the 1st quarter |

Median |

Limit of the 3rd quarter |

Maximum |

Robust residual standard error |

R² |

|

–83.781 |

9.671 |

3.362 |

21.989 |

365.574 |

22.8 |

0.53 |

The dependent variable was the cycle time (s) needed to process one tree as well as the sum of the process stages driving and processing. The independent variables operator, day/night and method had a significant influence on productivity (Table 6). It was shown that the harvesting cycle timer per tree was reduced in the semi-mechanized harvesting systems by 6.416 s, 6.417 s, and 10.587 s compared to CS1 for ES3, ES2, and ES1, respectively. When comparing the two harvester operators, harvesting cycle per tree lasted 28.107 s longer when trees where felled and processed by harvester operator 2. Moreover, under daylight conditions, the harvester cycle time per tree was redcued by 6.461 s compared to night conditions.

Table 6 Influence of significant parameters on cycle time for processing one tree (in seconds)

|

Coefficients: |

Estimate |

Std. Error |

T value |

Pr(>|t|) |

|

Intercept; The expected value of the response when all predictors are zero |

62.091 |

2.418 |

25.681 |

< 2e–16 *** |

|

Operator – operator 2; Operator 1 is the baseline group (dummy coding). Estimate is the difference between operator 1 and 2 |

28.107 |

1.740 |

16.149 |

< 2e–16 *** |

|

Day/night – day; Night is the baseline group (dummy coding). Estimate is the difference between night and day |

–6.461 |

1.658 |

–3.896 |

0.000101 *** |

|

ES3; CS1 is the baseline group (dummy coding). Estimate is the difference between the methods CS1 and ES3 |

–6.416 |

2.240 |

–2.865 |

0.004223 ** |

|

ES2; CS1 is the baseline group (dummy coding). Estimate is the difference between the methods CS1 and ES2 |

–6.417 |

2.185 |

–2.937 |

0.003353 ** |

|

ES1; CS1 is the baseline group (dummy coding). Estimate is the difference between the methods CS1 and ES1 |

–10.587 |

2.164 |

–4.893 |

1.08e–06 *** |

It should be noted here that the calculation of costs and productivity in the previous chapters involves an interpolation of different operators (Eq. 5). In contrast, the original values were used to create the productivity model with a multivariate multiple linear regression (Table 5, 6). The processing time per tree increased by 28.1 s for operator 2 compared to operator 1. When working during the day, the time decreased by 6.5 s compared to working at night. Compared to CS1, the time decreased by 6.4 s in ES3 and ES2 and by 10.6 s in ES1. The R² value is 0.528, so 52.8% of the variability in the data can be explained by the productivity model.

3.4 Damage to the Remaining Stand

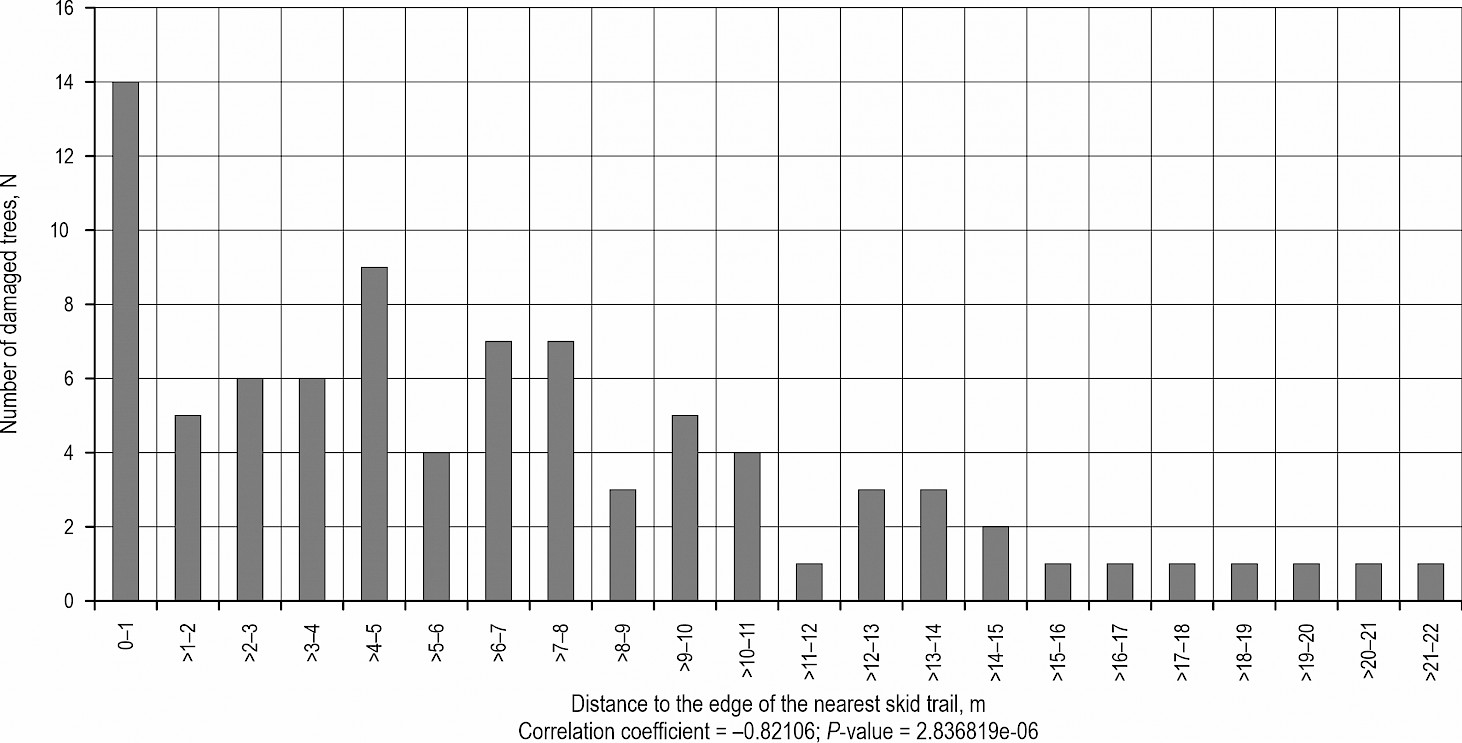

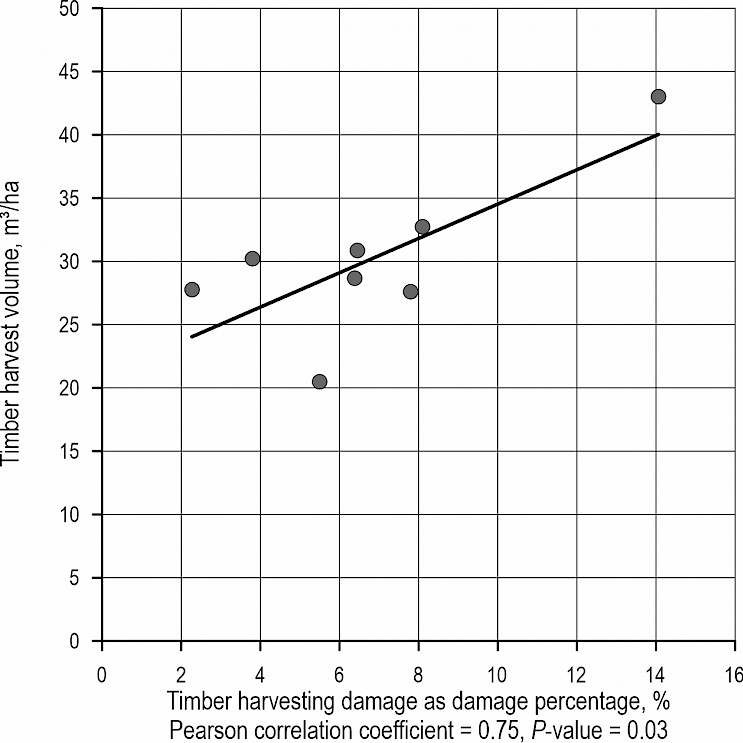

A total of 86 out of 1335 visually analyzed trees were found to be freshly damaged (with reference to the specified size and depth of the wound) from the timber harvesting operation. This corresponds to an average damage percentage of 6.4% for the whole area. The proportion of damaged trees does not differ significantly between the four harvesting methods (9.5% for CS1, 5.3% for ES3, 7.2% for ES2, and 5.7% for ES1). The chi-square test yielded a p-value of 0.29. Partially mechanized harvesting methods using ES do not result in more damage from harvesting than fully mechanized harvesting methods using CS. The damaged trees were, on average, 6.7 m away from the edge of the nearest skid trail. Moreover, the distance from the damaged trees to the nearest skid trail does not differ significantly between the different harvesting methods. A strong significant negative correlation was observed between the distance to the skid road and the number of damaged trees: The greater the distance to the skid road, the fewer damaged trees were recorded (Fig. 5).

Fig. 5 Distance of damaged trees to the edge of the neighbouring skid trail

A correlation analysis between the wood harvest volume per hectare and the number of damaged trees as a damage percentage shows a rather strong correlation between harvest quantities and damage percentage (Fig. 6). The damage on remaining trees was assessed for each of the eight different harvesting areas (Fig. 3) and analyzed in relation to the timber harvest volumes of the respective areas (Table 1). The correlation between the timber harvest damage and the timber harvest quantity is significant: The more timber is harvested, the higher the damage percentage.

Fig. 6 Timber harvest volume per hectare and damaged trees as damage percentage

4. Discussion

4.1 Productivity and Costs

The cost calculations in this study are based on data from German Centre for Forest Work and Technology (KWF 2024) and are relatively high compared to other studies. For a smaller harvester Timberjack 1270D, that can be used for thinning operations in pine stands too, Mizaras et al. (2008) calculate the costs with €67.5 per hour, while Mederski (2006) calculates €44.39 per hour for a comparable Timberjack 1270B. Jiroušek et al. (2007) calculate with €99.69–116.83 per hour for three different classes of harvesters. The €233.04 per hour for the harvester calculated in this study is partly due to the fact that the calculated interest rate of 8% is quite high, while the depreciation period of 10,500 PMH is quite low, and the labour costs are quite high with €44.60 per hour compared to €12 per hour used by Jiroušek et al. (2007). In practice these figures may vary considerably depending on the calculations of the respective company.

The choice of the optimal harvesting method always depends on the respective stand and site conditions: In very dense stands, for example, it may be necessary to have a first harvester pass before the motor-manual fellings in the midfield. Thus, there is enough space for safe and proper felling. The results of the present study showed that the timber harvesting methods with ES had higher timber harvesting costs than the method with CS (CS1 29.18 €/m³, ES3 34.56 €/m³, ES2 32.41 €/m³, and ES1 30.40 €/m³), although there are major differences between the various ES methods. The productivity of the harvester in the three ES methods increases as the number of harvester passes decreases to 3, 2 and 1, respectively (13.87 to 14.09 to 15.99 m³/h). Similarly to the research of Mederski et al. (2018), it was observed that 1) harvester productivity was lower in 2-pass ES2 (3.74 m³/PMH15) than in CS1 (4.67 m³/h) or ES1 (4.42 m³/h) and, 2) forwarder productivity was higher with ES (5.25 – 5.35 m³/h) than with CS (4.33 m³/h) due to higher volumes at skid trails. In contrast to Mederski's study, harvester productivity in the semi-mechanized system with one harvester pass exceeds productivity in the fully mechanized system. However, it should be noted that the 31-year-old pines in Mederski's study were much smaller (mean DBH 13 cm, mean height 11 m) than those examined here. As in this study, the partially mechanized method with ES and winching in the study of Berendt et al. (2018) was more expensive than the theoretically calculated fully mechanized method with CS (30.31 to 22.26 €/m³), whereby the harvester and forwarder costs were found to be higher in the CS method (8.58 to 10.90 €/m³, 7.80 to 11.71 €/m³). However, the study of Berendt et al. (2018) is only comparable to a limited extent, as the main tree species in that study were beech and spruce and a different machine was used for winching with a mini forestry crawler, and all motor-manually felled trees were winched. In another study by Wächter (2021), computer simulations were used to show that in spruce stands older than 50 years the cumulative pre-utilization yields of methods with ES exceed those of CS. This can be attributed to positive yield-related effects due to smaller skid trail area in the simulation. The profitability disadvantage from increasing the skid trail spacing from CS to ES is between 7 and 14% of the profitability of ES, depending on the assumed calculation interest rate. As in our study, the wood harvest with ES is more expensive than the CS methods. Frutig et al. (2016) came to similar results with model calculations for spruce stands in Switzerland. Here too, the timber harvesting costs for CS at CHF 33/m³ are lower than those of ES at up to CHF 41/m³. Nevertheless, in the calculations of Frutig et al. (2016), the higher short-term costs of ES can be offset in the long term by higher timber growth and less damage to trees, which leads to optimal skid trail distances of 30–50 m.

In accordance with the literature, the first hypothesis in this study was therefore confirmed:

Semi-mechanized timber harvesting methods with ES are more expensive than fully mechanized timber harvesting methods, whereby the productivity of harvesters and forwarders is higher in ES than in CS. This is due to the shorter distances that need to be driven by the machines and a higher concentration of timber next to skid trails, resulting in higher forwarder productivity.

During felling with chainsaw, the productivity in ES1 was lower than in ES3 and ES2. A possible explanation for this is the fact that in ES1, in contrast to ES2 and ES3, the motor-manual felling took place before the harvester was used. Thus, the felling conditions were much more challenging. The forest workers had to independently assess which marked trees were within boom reach of the harvester and which had to be felled by chainsaw. As a result, the skid trails were not so easily recognizable because they had not yet been driven on and there were no processed logs next to them. Felling in the direction of the skid trails may have been more difficult in some cases, as the trees next to the skid trail had not yet been felled by the harvester. Several studies analyzed motor-manual felling but, to the best of our knowledge, no study has compared the specific circumstance of felling before or after the pass of a harvester in a semi-mechanical method with ES. Based on our observations, we consider that the productivity of motor-manual felling in the midfield could be improved with increased experience or through special training. As seen by harvester operators, the performance is often doubled after a learning phase (Purfürst 2010). The effect of increased productivity of the motor-manual fellings on the overall timber harvesting costs should be further investigated.

The second hypothesis in this study was confirmed:

The productivity of motor-manual felling decreases if the trees are felled before the harvester is used, but the total timber harvesting costs are lower in this case due to the higher productivity of the harvester.

All in all, from the semi-mechanized wood harvesting methods with ES, ES1 with chainsaw felling before the harvester had the lowest costs. The proportion of unprocessed lying marked trees, at 1.5% of the timber harvest, also appears to be within a reasonable range. When comparing ES1 with CS1, the question arises as to how the higher timber harvesting costs can be justified to the forest owners. The increased wood harvesting costs in the study were partially but not completely offset by higher wood prices that could be achieved through the FSC-certification.

At the same time, the productivity of chainsaw felling is lowest in ES1 (Fig.4). Attempts should therefore be made to optimize chainsaw felling before the harvester. Possible options are as follows:

better training and more practice for the working group

better equipment, especially lighter clothing

more communication with the harvester, e.g. via a shared radio

making it easier to select the trees to be felled manually by marking them with a different colour or symbol.

Another interesting point of the study is the difference in the performance of the harvester and forwarder machines with or without daylight. The test showed that harvesters and forwarders work more slowly at night, which is consistent with the study of Pasicott and Murphy (2013). However, in this study it was not possible to attribute the wood harvest damage to work during the day or night. It is conceivable that more damage is caused at night because the harvester pushes the trunks into areas outside its headlights, particularly when processing motor-manually felled trees. Further investigations are needed to verify this. It has already been shown by Bembenek et al. (2020) that day verses night has a significant influence on residual stand damage.

4.2 Damage to Remaining Stand

The damage percentage within the plots of different harvesting methods varied between 5.3 and 9.5%, and the highest damage percentage was observed in CS1. This trend is consistent with the fact that trees are more prone to damage when they are closer to the skid trail and vice versa. This was also shown by other studies (Frutig et al. 2016, Nill 2011). In contrast to the analysis by Frutig et al. (2016) and the studies by Morat et al. (1998), Nakou et al. (2014), Sauter and Busmann (1994), this study could not determine that wood harvest damage increases with increasing skid trail distance. At the same time, the harvest quantity of 31.45 m³/ha is higher here than in the ES methods (Table 1) and the study showed a significant correlation there. This aligns with the observations of Nakou et al. (2014). However, the relatively small difference in the harvest quantity of 8% does not completely explain the difference in the percentage of damage. Rather, it seems to be crucial that the wood harvest method is designed to keep equipment on the trails (Han and Kellogg 2000). In the area with the highest damage percentage (14.1%), it was observed that the harvester operator left the skid trail tracks more often than in other areas (6.4% of damage) to reach trees. However, the frequency of the harvester front axle leaving the skid trail track was not recorded during the test and thus cannot be quantified in more detail.

The third hypothesis in the study has been refuted:

The damage to the remaining trees is dependent on the timber harvesting system, with a higher proportion of damaged trees in the fully mechanized system due to smaller skid trail distances with more endangered edge trees.

4.3 Unprocessed Trees

Another point of interest in this study is the marked trees remaining unprocessed on the area after logging. It is noticeable here that even in fully mechanized CS1, a high proportion of marked trees were not processed (Table 1). It seems that the length of the harvester boom (at 8.6 m) was too short to reach all marked trees. In some cases, it was observed that the harvester operator decided to trespass the skid trail border in order to reach a tree. This is prohibited by most state forest departments and in PEFC- or FSC-certified forests in Germany for soil protection reasons. When comparing the unprocessed trees, CS1 had the highest share with 15.6 % followed by ES1 (14.4 %), ES2 (10.0 %) and ES3 (0.3 %), respectively. Interestingly, it was noticed after the timber harvesting that in ES2 most of the unprocessed trees were lying. This is due to the fact that the trees felled motor-manually in the midfield were not reachable by the harvester or the harvester operator did not see them. In contrast, only a small proportion of marked trees remained lying in the forest in ES1 and ES3 (Table 1). While standing trees not felled can be harvested during the following harvest operation, the lying marked trees can remain lying deadwood in order to serve important ecological functions. Increasing the deadwood in the forest stand increases biodiversity (Albis and Miguel 2023) and improves water storage (Anderegg et al. 2018). For this reason, enrichment with deadwood is also a funding criterion in the German government funding program for climate-adapted forests (BMEL 2022). Even though an exact amount of deadwood is not specified in the corresponding funding guidelines, it refers to an evaluation scheme that specifies at least three pieces of standing and lying deadwood per hectare for pine forests, which corresponds to approx. 6 m³/ha (BfN and BLAK 2017). The volume of unprocessed marked trees was below 6 m³ in all four harvesting methods. Moreover, the bark of the unprocessed standing trees has to be curled in order to become dead wood.

4.4 Sustainability

Looking at the environmental impacts of forest stands with extended skid trail spacings, it can be assumed that the short-term disadvantages of semi-mechanized timber harvesting methods, such as higher harvesting costs, can be offset in the long term by their advantages. Advantages are especially evident in the positive environmental effects. The challenge here is that the impact on the environment depends heavily on the respective site conditions and is very difficult to quantify in economic terms. In addition, soil damage and damage to regeneration following logging are rarely systematically recorded (Picchio et al. 2020). In multifunctional forests, long-term environmental compatibility must be given priority over short-term economic or social benefits (UBA 2021). It has been shown that skid trails at a distance of 40 m can have higher economic value overall than skid trails at a distance of 20 m, despite the higher timber harvesting costs, if the loss of productive forest area due to skid trails is included in the long-term economic consideration (Wächter 2021). Also, FSC has introduced an expectation of wider spacing between skid trails in Germany FSC 2024a). According to the currently valid FSC standard in Germany, 10% of the total productive wooden floor area may be used as a skid trail in the long term and 13.5% in the medium term. This is justified by the fact that the actual forest area (productive woodland area) remains relatively large, more CO2 can be stored in the forest, less forest soil is lost to the skid trails and soil aeration and water conductivity are less affected (FSC 2022). It should be noted that due to the canopy provided by edge trees, it is not the case that the entire width of skid trails is excluded from utilization.

Occupational safety is of great importance when comparing timber harvesting methods (Keller et al. 2021). Despite this, workload and occupational safety is currently a marginal field in forestry research (Bačić et al. 2024). It has long been known that fully mechanized methods perform better in this regard than partially mechanized methods due to the strenuous and dangerous work with chainsaw and cable winches that is involved with the latter (Staaf et al.1984, Stenzel et al. 1985, Berendt et al. 2020a, Halilović et al. 2021). Another point worth discussing in this context is the handling of hanging trees. For simplicity and cost reasons, the hanging trees are often pulled down with the cable tractor together with the winching operations. In so doing, the hanging trees remain as an accident risk until the cable tractor pulls them down. However, for safety reasons, hanging trees have to be brought down immediately (SVLFG 2017). To enable the forest worker group to work as safely as possible, they should be equipped at the very least with a capstand winch and, ideally, with a cable winch. Besides improving work safety, the use of a cable winch for each working group might reduce overall cost both through the limitation of transportation costs and optimization of the timber harvesting system. For example, this may enable the work crew to carry out the chainsaw felling and any necessary winching to the skid trails in one step. In general, further investigations are needed to improve working conditions during chainsaw felling.

5. Conclusions

The following conclusions can be drawn from this study:

Semi-mechanized timber harvesting methods with ES had higher overall timber harvesting costs than fully mechanized timber harvesting. The lowered costs of harvester (ES1) and forwarder (ES3, ES2 and ES1) could not compensate for the increased costs due to motor manual fellings (ES3, ES2 and ES1) outside the boom reach of the harvester and pre-winching operation (ES3)

The productivity of the harvester in ES increases as the number of harvester passes decreases. Productivity can be increased if motor-manual felling is carried out before the harvester pass

The forwarder productivity is higher in ES than in CS

Although the percentage of residual stand damage in CS is higher than in ES, no significant difference was observed across the methods

Further research on the environmental balance is necessary to answer the overarching question of whether the positive effects of extended skid trail spacing can compensate, in a longer term, for the resulting higher timber harvesting costs.

Acknowledgments

This study was undertaken within the framework of the project »ADAPT-Wald-Holz«, which is funded by the German Federal Ministry of Research, Technology and Space (BMFTR) in the funding measure REGULUS (grant number: 033L301A). The authors thank the Brandenburg State Forestry Authority (Lfb) for their support as well as the forestry workers, machine operators and foresters, and the measuring assistants Hanna Wagner and Carlotta Michel.

6. References

Ackerman, P., Belbo, H., Eliasson, L., Jong, A de., Lazdins, A., Lyons, J., 2014: The COST model for calculation of forest operations costs. International Journal of Forest Engineering 25(1): 75–81. https://doi.org/10.1080/14942119.2014.903711

Albis, L., Miguel, C., 2023: Effect of forest management on forest structure and its influence on forest biodiversity in temperate forests of central Europe. Albert-Ludwigs-Universität Freiburg.

Amt für Statistik Berlin-Brandenburg 2024: Statistischer Bericht C V 1 – j / 23, Holzeinschlag im Land Brandenburg 2023 - Statistical report C V 1 – j / 23, Timber harvesting in the state of Brandenburg in 2023, Potsdam. Available online: https://download.statistik-berlin-brandenburg.de/e2d8753a068440e8/a3c358da4696/SB_C05-01-00_2023j01_BB.pdf

Anderegg, W.R.L., Konings, A.G., Trugman, A.T., Yu, K., Bowling, D.R., Gabbitas, R., Karp, D.S., Pacala, S., Sperry, J.S., Sulman, B.N. Zenes, N., 2018: Hydraulic diversity of forests regulates ecosystem resilience during drought. Nature 561 (7724): 538–541. https://doi.org/10.1038/s41586-018-0539-7

Anderson, T.W., Darling, D.A., 1952: Asymptotic theory of certain »Goodness of fit« criteria Based on stochastic processes. The Annals of Mathematical Statistics 23(2): 193–212.

Bačić, M., Landekić, M., Pandur, Z., Šušnjar, M., Šporčić, M., Nevečerel, H., Lepoglavec, K., 2024: Forestry ergonomics publications in the last decade: A review. Forests 15(4): 616. https://doi.org/10.3390/f15040616

Bauer, D., 1972: Constructing confidence sets using rank statistics. Journal of the American Statistical Association 67(339): 687–690. https://doi.org/10.1080/01621459.1972.10481279

Baysf, B.S., 2010: Bodenschutz bei den Bayerischen Staatsforsten – Soil protection in the Bavarian State Forests, Regensburg. Available online: https://www.baysf.de/fileadmin/user_upload/03-wald_schuetzen/pdf/Broschuere_Bodenschutz_03.pdf

Behrendt, K., 2010: Aktuelle Schadensanalysen nach der hochmechanisierten Holzernte. Vergleich der bestehenden Methoden von Bonus-Malus-System Probekreisverfahren Gedanken zu einem neuen Verfahren - Current damage analyses following highly mechanized timber harvesting. Comparison of existing methods: bonus-malus system, trial circle method, thoughts on a new method. Bachelor thesis, Eberswalde. Available on: https://web.s.ebscohost.com/ehost/detail/detail?vid=3&sid=fa7955d9-f3f4-4f0e-953d-1b4def3cf2bd%40redis&bdata=Jmxhbmc9ZGUmc2l0ZT1laG9zdC1saXZl#AN=hne.73598&db=cat09127a (accessed on July 28, 2023)

Bembenek, M., Tsioras, P.A., Karaszewski, Z., Zawieja, B., Bakinowska, E., Mederski, P.S., 2020,:Effect of day or night and cumulative shift time on the frequency of tree damage during CTL harvesting in various stand conditions. Forests 11(7): 743. https://doi.org/10.3390/f11070743

Benisiewicz, B., Pawełczyk, S., Niccoli, F., Kabala, J.P. Battipaglia, G., 2024: Drought impact on eco-physiological responses and growth performance of healthy and declining Pinus sylvestris L. trees growing in a dry area of southern Poland. Forests 15(5): 741. https://doi.org/10.3390/f15050741

Berendt, F., Fortin, M., Jaeger, D., Schweier, J., 2017:How climate change will affect forest composition and forest operations in Baden-Württemberg – A GIS-based case study approach. Forests 8(8): 298. https://doi.org/10.3390/f8080298

Berendt, F., Fortin, M., Suchomel, C., Schweier, J., 2018: Productivity, costs, and selected environmental impacts of remote-controlled mini forestry crawlers. Forests 9(10): 591. https://doi.org/10.3390/f9100591

Berendt, F., Hoffmann, S., Jaeger, D., Prettin, S., Schweier, J., 2020a: Application of spiroergometry to determine work metabolism related strain in the course of cable work with a mini forestry crawler. International Journal of Forest Engineering 31(2): 114–125. https://doi.org/10.1080/14942119.2020.1735198

Berendt, F., Tolosana, E., Hoffmann, S., Alonso, P., Schweier, J., 2020b: Harvester productivity in inclined terrain with extended machine operating trail intervals: A German case study comparison of standing and bunched trees. Sustainability 12(21): 9168. https://doi.org/10.3390/su12219168

Best, D.J., Roberts, D.E., 1975: Algorithm AS 89: The upper tail probabilities of Spearman's Rho. Applied Statistics 24(3): 377-379. https://doi.org/10.2307/2347111

BfN., BLAK, 2017: Bewertungsschemata für die Bewertung des Erhaltungsgrades von Arten und Lebensraumtypen als Grundlage für ein bundesweites FFH-Monitoring. Teil II: Lebensraumtypen nach Anhang I der FFH-Richtlinie (mit Ausnahme der marinen und Küstenlebensräume) Stand: Oktober 2017 – Assessment schemes for evaluating the conservation status of species and habitat types as a basis for nationwide FFH monitoring. Part II: Habitat types according to Annex I of the FFH Directive (with the exception of marine and coastal habitats) Status: October 2017, Bundesamt für Naturschutz. Available online: https://www.bfn.de/publikationen/bfn-schriften/bfn-schriften-481-bewertungsschemata-fuer-die-bewertung-des

BMEL, 2022: Richtlinie für Zuwendungen zu einem klimaangepassten Waldmanagement – Guidelines for subsidies for climate-adapted forest management. Available online: https://www.klimaanpassung-wald.de/fileadmin/Projekte/2023/F%C3%96SL/rl_klimaanpassung_2023.pdf (accessed on August 28, 2024)

BMEL, 2024a: Der Wald in Deutschland - Ausgewählte Ergebnisse der vierten Bundeswaldinventur – Forests in Germany – Selected results of the fourth National Forest Inventory, Bonn. Available online: https://www.bundeswaldinventur.de/fileadmin/Projekte/2024/bundeswaldinventur/Downloads/BWI-2022_Broschuere_bf-neu_01.pdf

BMEL, 2024b: Ergebnisse der Waldzustandserhebung 2023 – Results of the 2023 Forest Condition Survey, Bonn. Available online: https://www.bmel.de/SharedDocs/Downloads/DE/Broschueren/waldzustandserhebung-2023.pdf?__blob=publicationFile&v=9

BMEL, 2024c: Holzmarktbericht 2023, Abschlussergebnisse für die Forst- und Holzwirtschaft des Wirtschaftsjahres 2023 – Wood Market Report 2023, Final Results for the Forestry and Wood Industry for the 2023 Financial Year, Bonn. Available online: https://www.bmel.de/SharedDocs/Downloads/DE/Broschueren/holzmarktbericht-aktuell.pdf?__blob=publicationFile&v=4

Borchert, H., Aurenhammer, P.K., Breinig, L., Spinelli, R., Magagnotti, N., Labelle, E.R., 2024: Effect of season and machine type on performance of semi- and fully mechanized harvesting systems in beech-dominated stands. Croatian journal of forest engineering 45(2): 237–249. https://doi.org/10.5552/crojfe.2024.2281

Borz, S.A., Crăciun, B.C., Marcu, M.V., Iordache, E., Proto, A.R., 2023:Could timber winching operations be cleaner? An evaluation of two options in terms of residual stand damage, soil disturbance and operational efficiency. European Journal of Forest Research 142(3): 475–491. https://doi.org/10.1007/s10342-023-01536-1

Bösch, M., Elsasser, P., Franz, K., Lorenz, M., Moning, C., Olschewski, R., Rödl, A., Schneider, H., Schröppel, B., Weller, P., 2018: Forest ecosystem services in rural areas of Germany: Insights from the national TEEB study. Ecosystem Services 31(part A): 77–83. https://doi.org/10.1016/j.ecoser.2018.03.014

Brown, M.B., Forsythe, A.B., 1974: Robust tests for the equality of variances. Journal of the American Statistical Association 69(346): 364–367. http://dx.doi.org/10.1080/01621459.1974.10482955

Cambi, M., Certini, G., Neri, F., Marchi, E., 2015: The impact of heavy traffic on forest soils: A review. Forest Ecology and Management 338: 124–138. https://doi.org/10.1016/j.foreco.2014.11.022

Christensen, B., Christensen, S., Missong, M., 2019: Statistik klipp & klar – Statistics clear & concise. Springer Gabler, Wiesbaden, Germany, Heidelberg. https://doi.org/10.1007/978-3-658-27218-0

Dunn, O.J., 1961: Multiple comparisons among means. Journal of the American Statistical Association 56(293): 52–64. https://doi.org/10.1080/01621459.1961.10482090

Eriksson, M., Lindroos, O., 2014: Productivity of harvesters and forwarders in CTL operations in northern Sweden based on large follow-up datasets. International Journal of Forest Engineering 25(3): 179–200. https://doi.org/10.1080/14942119.2014.974309

Forest Stewardship Council (FSC) Deutschland, 2022: 'Themenpapier-FSC-Klimastabile-Waelder – Topic paper – FSC climate-stable forests'. Available online: https://www.fsc-deutschland.de/wp-content/uploads/Themenpapier-FSC-Klimastabile-Waelder.pdf (accessed on September 06, 2024)

Forest Stewardship Council (FSC) Deutschland, 2024a: Deutscher FSC-standard: version 3-1 – German FSC standard: version 3–1, Freiburg. Available online: https://www.fsc-deutschland.de/wp-content/uploads/2024-09-10-Deutscher-FSC-Standard-3-1.pdf

Forest Stewardship Council (FSC) Deutschland, 2024b: Zahlen und Fakten – die FSC-Waldkarte, Internetdokument – Facts and figures – the FSC forest map, Internet document, FSC Deutschland. Available online: https://www.fsc-deutschland.de/wald/zahlen-und-fakten/ (accessed on January 17, 2025)

Forstliches Bildungszentrum Königsbronn, 2009: Das Königsbronner Harvesterverfahren (KVH) – The Königsbronn harvester method (KVH). Available online: https://fbz-koenigsbronn.forstbw.de/fileadmin/fbz_koe/pdf/KoenigsbronnerHarvesterVerfahren.pdf (accessed on July 28, 2023)

Frutig, F., Thees, O., Ammann, P., Lüscher, P., Rotach, P., 2016: Holzerntekosten und Mindererlöse bei verschiedenen Rückegassenabständen in Fichtenbeständen – Wood harvesting costs and reduced revenues for different skid trail distances in spruce stands. Schweizerische Zeitschrift fur Forstwesen 167(2): 64–72. https://doi.org/10.3188/szf.2016.0064

FVA, 2003: Richtlinie der Landesforstverwaltung Baden-Württemberg zur Feinerschließung von Waldbeständen – Guideline of the Baden-Württemberg State Forestry Administration on the detailed development of forest stands. Available online: https://www.fva-bw.de/fileadmin/publikationen/sonstiges/rlo_befahrung.pdf

Ghaffariyan, M., 2010: Review of European biomass harvesting technologies. Silva Balcanica 11(1): 5–20.

Ghaffariyan, M.R., Brown, M., 2013: Selecting the efficient harvesting method using multiple-criteria analysis: A case study in south-west Western Australia. Journal of Forest Science 59(12): 479–486. https://doi.org/10.17221/45/2013-JFS

Grunewald, K., Meier, S., Bastian, O., Syrbe, R-U., Walz, U., Schweppe-Kraft, B., Lampkin, N., Elsasser, P., Altenbrunn, K., Köthke, M., Lorenz, M., Meyerhoff, J., Haase, D., Gerhard, P., Kochan, B., Neumann, I., Richter, B., Schäfer, A., Schwarz, S., Ohnesorge, B., Bieling, C., Schleyer, C., Plieninger, T., 2023: Bewertung von Ökosystemen und deren Leistungen in Deutschland - Assessment of ecosystems and their services in Germany' in Ökosystemleistungen. Konzept, Methoden, Bewertungs- und Steuerungsansätze, eds. K. Grunewald, O. Bastian, Springer Spektrum, Berlin, 251–478. https://doi.org/10.1007/978-3-662-65916-8_5

Halilović, V., Musić, J., Knežević, J., 2021: Physiological workload of chainsaw felling and processing workers in uneven-aged mixed stands. Radovi Šumarskog fakulteta Univerziteta u Sarajevu 51(2): 26–34. https://doi.org/10.54652/RSF.2021.V51.I2.357

Han, H-S., Kellogg, L.D., 2000: Damage characteristics in young douglas-fir stands from commercial thinning with four timber harvesting systems. Western Journal of Applied Forestry 15(1): 27–33. https://doi.org/10.1093/wjaf/15.1.27

Hennek, M., 2022: Der Einfluss des Rückegassenabstandes auf die Wertentwicklung von Waldbeständen – The influence of skid trail spacing on the value development of forest stands. Dissertation, Dresden. Available online: https://d-nb.info/125617145X/34

Hollander, M., Wolfe, A.D., 1973: Nonparametric statistical methods. John Wiley and Sons, New York, 848 p.

Ibisch, P.L., Blumröder, J.S., 2020: Waldentwicklung und Ökosystemleistungen im Klimawandel: aktuelle waldökologische Ergebnisse und Schlussfolgerungen aus Brandenburg Empfehlungen für einen strategischen und ökosystembasierten Umgang mit der Waldkrise. Beitrag zur Brandenburger Waldkonferenz 2020 – Forest development and ecosystem services in climate change: current forest ecology findings and conclusions from Brandenburg Recommendations for a strategic and ecosystem-based approach to the forest crisis. Contribution to the Brandenburg Forest Conference 2020. Available online: https://www.researchgate.net/publication/344891893_Waldentwicklung_und_Okosystemleistungen_im_Klimawandel_aktuelle_waldokologische_Ergebnisse_und_Schlussfolgerungen_aus_Brandenburg_Empfehlungen_fur_einen_strategischen_und_okosystembasierten_Umgang_mit

IPCC, 2023: Synthesis report of the IPCC sixth assessment report (AR6). Longer Report. Available online: https://www.ipcc.ch/report/ar6/syr/downloads/report/IPCC_AR6_SYR_LongerReport.pdf (accessed on July 03, 2023)

Jiroušek, R., Klvac, R., Skoupý, A., 2007: Productivity and costs of the mechanised cut-to-length wood harvesting system in clear-felling operations. Journal of Forest Sciende 53(10): 476–482. https://doi.org/10.17221/2088-JFS

Johansson, M., Lundbäck, M., Lindroos, O., 2024: Trade-offs between stump-to-roadside lead time and harvesting cost, when using different number of operators in a harvester-forwarder system. European Journal of Forest Research 143(6): 1667–1683. https://doi.org/10.1007/s10342-024-01713-w

Keller, E., Newman, J.E., Ortmann, A., Jorm, L.R., Chambers, G.M., 2021: How much is a human life worth? A systematic review. Value in health 24(10): 1531–1541. https://doi.org/10.1016/j.jval.2021.04.003

Kizha, A.R., Nahor, E., Coogen, N., Louis, L.T., George, A.K., 2021: Residual stand damage under different harvesting methods and mitigation strategies. Sustainability 13(14): 7641. https://doi.org/10.3390/su13147641

KWF, 2023: OUTREACH. Available online: https://kwf2020.kwf-online.de/portfolio/outreach/ (accessed on July 13, 2023)

KWF, 2024: Datenbasis Waldarbeit & Forsttechnik – Forestry work & forestry technology database. Available online: https://dbwaldarbeit.kwf-online.de/impressum/ (accessed on July 18, 2024)

Landesforstbetrieb Brandenburg (Lfb), 2023: Erweiterung FSC-Flächen, Internetdoukument – Expansion of FSC areas, Internet document. Available online: https://forst.brandenburg.de/lfb/de/erweiterung-fsc-flaechen/ (accessed on August 17, 2023)

Lenz, J., 2017: Vergleich von Holzernteverfahren im erweiterten Rückegassenabstand bei der hochmechanisierten Holzernte – Comparison of timber harvesting methods with extended skid trail spacing in highly mechanized timber harvesting. Bachelorthesis, Eberswalde.

Lundbäck, M., Häggström, C .,Nordfjell, T., 2021: Worldwide trends in methods for harvesting and extracting industrial roundwood. International Journal of Forest Engineering 32(3): 202–215. https://doi.org/10.1080/14942119.2021.1906617

Magagnotti, N., Spinelli, R., 2011: Integrating animal and mechanical operations in protected areas. Croatian journal of forest engineering 32(2): 488–499.

Magagnotti, N., Spinelli, R., 2012: Replacing steel cable with synthetic rope to reduce operator workload during log winching operations. Small-scale Forestry 11(2): 223–236. https://doi.org/10.1007/s11842-011-9180-0

Marchi, E., Chung, W., Visser, R., Abbas, D., Nordfjell, T., Mederski, P.S., McEwan, A., Brink, M., Laschi, A., 2018: Sustainable forest operations (SFO): A new paradigm in a changing world and climate. The Science of the total environment 634: 1385–1397. https://doi.org/10.1016/j.scitotenv.2018.04.084

Mederski, P., Venanzi, R., Bembenek, M., Karaszewski, Z., Rosińska, M., Pilarek, Z., Luchenti, I., Surus, M., 2018: Designing thinning operations in 2nd age class pine stands – Economic and environmental implications. Forests 9(6): 335. https://doi.org/10.3390/f9060335

Mederski, P.S., 2006: A comparison of harvesting productivity and costs in thinning operations with and without midfield. Forest Ecology and Management 224(3): 286–296. https://doi.org/10.1016/j.foreco.2005.12.042

Meng, W., 1978: Baumverletzungen durch Transportvorgänge bei der Holzernte: Ausmaß und Verteilung, Folgeschäden am Holz und Versuch ihrer Bewertung – Tree damage caused by transport operations during timber harvesting: extent and distribution, consequential damage to timber, and attempts at assessment, Selbstverl. d. Landesforstverwaltung Baden-Württemberg, Stuttgart. Available online: https://agris.fao.org/search/en/providers/123819/records/647358e753aa8c8963077d58

Mizaras, S., Sadauskienë, L., Mizaraitë, D., 2008: Productivity of harvesting machines and costs of mechanized wood harvesting: Lithuanian case study. Baltic Forestry 14(2): 155–162.

MLUK, 2023: Waldzustandsbericht 2023 des Landes Brandenburg - 2023 Forest Condition Report for the State of Brandenburg, Potsdam. Available online: https://mluk.brandenburg.de/sixcms/media.php/9/Waldzustandsbericht-BB-2023.pdf

Morat, J., Forbrig, A., Graupner, J., 1998: Holzernteverfahren – vergleichende Erhebung und Beurteilung der Holzernteverfahren in der Bundesrepublik Deutschland – Timber harvesting methods – comparative survey and assessment of timber harvesting methods in the Federal Republic of Germany, KWF, Groß-Umstadt.

Nakou, A., Nill, M., Sauter, U.H., Kohnle, U., 2014: Rindenschäden durch Holzernte: Analysen, Modellierung und Evaluierung auf der Basis zweier Praxis-Grossversuche – Bark damages during harvesting operations: Analysis, modelling and evaluation on the basis of two large-scale studies. Allg Forst-Jagdztg 184(5/6): 97–112.

Nakou, A., Sauter, U.H., Kohnle, U., 2016: Improved models of harvest-induced bark damage. Annals of Forest Science 73(2): 233–246. https://doi.org/10.1007/s13595-015-0530-5

Nill, M., 2011: Rindenschäden durch Holzernte in Baden-Württemberg: Ursachen und Prognose – Bark damage caused by timber harvesting in Baden-Württemberg: causes and prognosis. Eigenverlag der FVA, Freiburg, 161 p.

Palander, T., Eronen, J., Kärhä, K., Ovaskainen, H., 2018: Development of a wood damage monitoring system for mechanized harvesting. Annals of Forest Research 61(2): 243–258. https://doi.org/10.15287/afr.2018.1084

Pasicott, P., Murphy, G.E., 2013: Effect of work schedule design on productivity of mechanised harvesting operations in Chile. New Zealand Journal of Forestry Science 43(1): 2. https://doi.org/10.1186/1179-5395-43-2

Picchio, R., Mederski, P.S., Tavankar, F, 2020: How and how much, do harvesting activities affect forest soil, regeneration and stands? Current Forestry Reports 6(2): 115–128. https://doi.org/10.1007/s40725-020-00113-8

Proto, A., Macrì, G., Visser, R., Russo, D., Zimbalatti, G., 2018: Comparison of timber extraction productivity between winch and grapple skidding: A case study in southern Italian forests. Forests 9(2): 61. https://doi.org/10.3390/f9020061

Purfürst, F.T., 2010: Learning curves of harvester operators. Croatian journal of forest engineering 31(2): 89–97.

R Foundation for Statistical Computing, 2023: A language and environment for statistical computing. R Core Team, Vienna, Austria. Available online: https://www.R-project.org/

REFA (ed.), 1998: Arbeitsstudien, Arbeitsorganisation und Qualitätsmanagement in der Forstwirtschaft – Work studies, work organization, and quality management in forestry, Verl. Inst. für Arbeitsorganisation, Stuttgart.

Richter, P., 2019: Forstpraktische Quantifizierung von Holzernteschäden nach der Durchforstung – Practical quantification of timber harvesting damage after thinning. Bachelorthesis, Eberswalde.

Sauter, U.H., Busmann, C., 1994: Bestandesschäden bei der Durchforstung von Fichtenbeständen mit Kranvollerntern unter Berücksichtigung unterschiedlicher Rückegassenabstände – Damage to stands during thinning of spruce stands with crane harvesters, taking into account different skid trail distances. Forsttechnische Informationen 12: 137–141.

Spinelli, R., Lombardini, C., Magagnotti, N., 2014:The effect of mechanization level and harvesting system on the thinning cost of Mediterranean softwood plantations. Silva Fennica 48(1): 1003. https://doi.org/10.14214/sf.1003

Staaf, K.A., Staaf, K.A.G., Wiksten, N., 1984: Tree harvesting techniques. Nijhoff/Junk, Dordrecht.

Stenzel, G., Walbridge, T.A., Pearce, J.K., 1985: Logging and pulpwood production. Wiley, New York, 358 p.

SVLFG, 2017: Unfallverhütungsvorschrift Forsten (VSG 4.3) – Accident prevention regulations for forestry (VSG 4.3). Available online: https://cdn.svlfg.de/fiona8-blobs/public/svlfgonpremiseproduction/5eef1437acda7060/19bb627832ef/vsg4_3-forsten.pdf

Thorpe, H.C., Thomas, S.C., Caspersen, J.P., 2008: Tree mortality following partial harvests is determined by skidding proximity. Ecological applications 18(7): 1652–1663. https://doi.org/10.1890/07-1697.1

UBA, U., 2021: Umweltschutz, Wald und nachhaltige Holznutzung in Deutschland – Environmental protection, forests, and sustainable timber use in Germany, 06813 Dessau-Roßlau. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/5750/publikationen/2021_hgp_umweltschutzwald_u_nachhaltigeholznutzung_bf.pdf (accessed on 14 August 2024)

Ursić, B., Vusić, D., Papa, I., Poršinsky, T., Zečić, Ž., Đuka, A., 2022: Damage to residual trees in thinning of broadleaf stand by mechanised harvesting system. Forests 13(1): 51. https://doi.org/10.3390/f13010051

Vusić, D., Šušnjar, M., Marchi, E., Spina, R., Zečić, Ž., Picchio, R., 2013: Skidding operations in thinning and shelterwood cut of mixed stands – Work productivity, energy inputs and emissions. Ecological Engineering 61(parta A): 216–223. https://doi.org/10.1016/j.ecoleng.2013.09.052

Wächter, M., 2021: Rentabilitätsanalyse unterschiedlicher Feinerschließungsoptionen und ökonomische Simulation verschiedener Befahrungseffekte am Beispiel der Fichte in Sachsen – Profitability analysis of different fine development options and economic simulation of various traffic effects using the example of spruce in Saxony. Dissertation, Dresden. Available online: https://tud.qucosa.de/landing-page/?tx_dlf[id]=https%3A%2F%2Ftud.qucosa.de%2Fapi%2Fqucosa%253A74422%2Fmets

Wessely, J., Essl, F., Fiedler, K., Gattringer, A., Hülber, B., Ignateva, O., Moser, D., Rammer, W., Dullinger, S., Seidl, R., 2024: A climate-induced tree species bottleneck for forest management in Europe. Nature ecology & evolution 8(6): 1–9. https://doi.org/10.1038/s41559-024-02406-8

Wirth, J., 2008: Pferde in der modernen Forstwirtschaft. Vergleich von Leistung und Pfleglichkeit zwischen Pferd und Seilschlepper beim Vorliefern von Fichten-Vollbäumen – Horses in modern forestry, comparison of performance and care between horses and cable tractors when transporting spruce full trees. Diplomarbeit, Rottenburg. Available online: http://institut-waldarbeit.de/fileadmin/Seiteninhalt/Diplom-_und_Bachelorarbeiten/Wirth__Julia/Pferde_in_der_modernen_Forstwirtschaft.pdf (accessed on August 17, 2023)

Yohai, V.J., Stahel, W.A., Zamar, R.H., 1991: A procedure for robust estimation and inference in linear regression. In: Directions in Robust Statistics and Diagnostics. The IMA Volumes in Mathematics and its Applications. Springer, New York. https://doi.org/10.1007/978-1-4612-4444-8_20

Appendix A

Table A1 Measuring points of the process sections in the time study

|

Machine |

Process section |

Measuring points |

Remarks |

|

Harvester |

Driving |

Trunk is released – Trunk is gripped |

Driving and crane movement are measured as 1 process section during logging. Short stops of up to 1 min are included in the driving time. Driving is the time in the system with the skid trails as borders of the system. |

|

Pure drive |

Wheels stop – Wheels start moving |

Travel times outside of processing, e.g. when changing skid trails or driving to refuel. Pure driving is the time outside the system, which means that the machine does not drive on the skid trails. |

|

|

Processing |

Trunk is gripped – Trunk is released |

Felling and processing are measured as 1 process section, including comments on lying trees that do not need to be felled, winched trees and standing trees without further differentiation. |

|

|

Cable tractor |

Driving |

Wheels stop – Wheels start moving |

Short stops of up to 1 min are included in the driving time. |

|

Cable pull–out |

Rope is pulled out – Rope is attached to the trunk |

The distance between the winch and the trunk to be pulled is also measured and noted |

|

|

Getting on/off |

Wheels stop – Rope is pulled out Rope is unhooked – Wheels start to move |

The time the driver needs to get in and out the cable tractor. |

|

|

Cable retraction |

Rope is attached to the trunk – Rope is detached from the trunk |

If the rope is disconnected in between due to a pulley or similar, this does not count as an interruption |

|

|

Forwarder |

Driving |

Wheels stop – Wheels start moving |

Short stops of up to 1 min are included in the driving time. Driving is the time in the system with the skid trails as borders of the system. Driving time outside the skid trails is measured as other pure working time outside the skid trail. |

|

Loading logs onto the truck |

Wheels stop – Trunk is gripped Trunk is released – Wheels start to move |

||

|

Unload logs |

Wheels stop – Wheels start moving |

Unloading the logs is completed when the stanchion basket is empty, travel movements during unloading are not recorded separately. |

|

|

Chainsaw |

Go to a tree |